Search by Topic

Innovation

DENSO Sponsors SAE WCX Digital Summit

We are pleased to share that DENSO is sponsoring SAE International’s 2021 WCX Digital Summit, taking place April 13-15. The sponsorship helps DENSO connect with industry leaders, while advancing the conversation of how the automotive world can create safer and more sustainable mobility through innovation and working together.

DENSO’s presence at this year’s show will include:

- A keynote presentation titled, “Edge Computing in ITS (Intelligent Transportation Systems),” on Wednesday, April 14, 11-11:30 a.m. ET. Roger Berg, vice president of North America Research and Development at DENSO, will discuss connectivity’s increasing role in mobility ecosystems.

- A panel called, “Leadership Summit: Evolution of the Vehicle Architecture,” on Tuesday, April 13, 4:15-5:30 p.m. ET. Mike Murzyn, vice president of Engineering in DENSO’s mobility products group, will discuss among others the growing need for collaboration in vehicle development as they become more complex.

To register, go here: https://bit.ly/3e19GpU

“I look forward to not only sharing how edge computing contributes to intelligent transportation systems, but also learning from other presenters about how they’re tackling our industry’s biggest issues,” said Berg. “SAE WCX is always a great give and take, underscoring the need for all of us to leverage each other’s strengths to make mobility cleaner, safer and more efficient.”

This year’s event arrives as DENSO is recommitting to its two great causes: “Green” – acting environmentally friendly – and “Peace of Mind” – creating seamless and safe mobility for all. This is part of Reborn 21, the company’s internal plan to build a leaner and more robust corporate structure and respond flexibly to new market needs. It will also propel DENSO toward its Long-term Policy 2030, focused on enriching mobility and the well-being of society.

Beyond 2030, DENSO aims to become carbon neutral by 2035. To accomplish this, the company is focusing on three areas: manufacturing, mobility products and energy use. DENSO has already begun the effort, recently launching its first CO2 plant at its Anjo Electrification Center in Japan to capture and recycle carbon and help power the facility.

New Lexus and Toyota Cars Feature Our ADAS Products

Today, our global headquarters announced we have developed products for Advanced Drive, an advanced driver assistance technology featured on the new Lexus LS and the new Toyota Mirai. Both vehicles, and our new technology, will be on the road this month!

Advanced driver assistance technologies are essential to helping drivers safely operate vehicles. The products that we have developed will support drivers on expressways and other motor-vehicle-only roadways, allowing the Advanced Drive system to detect hazardous situations, make decisions and assist driving under the driver’s supervision.

With these new products, we will contribute to advanced driver assistance technology that gives peace of mind to occupants and improves the safety of vehicles. They are part of our broader commitment to developing mobility technologies that help create safe and flexible mobility for drivers and pedestrians alike.

To learn more about the advanced driver assistance technologies we’re contributing, follow this link: https://bit.ly/3s4vmGS

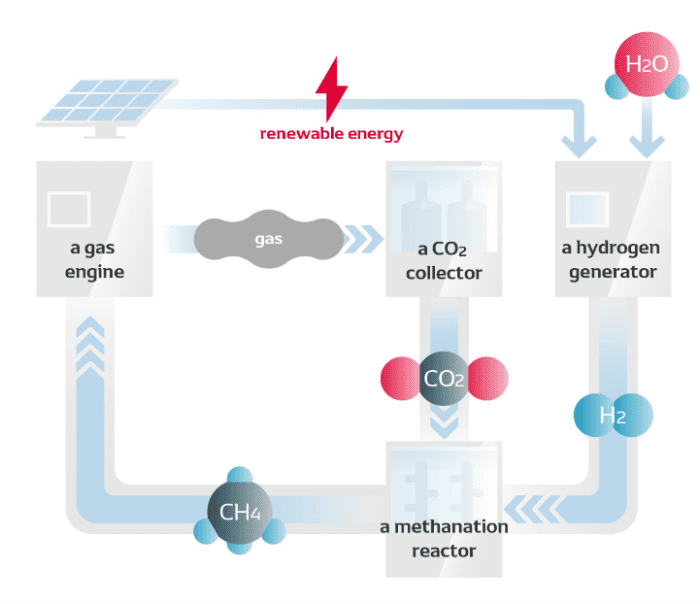

New CO2 Circulation Plant Supports Our Carbon Neutrality Goal

Today, our global headquarters announced that we have begun testing a CO2 circulation plant at our Anjo Plant’s Electrification Innovation Center. The new plant will capture CO2 generated by the plant and recycle it as an energy source for the facility, a capability that supports our efforts to eliminate CO2 emissions from our facilities.

More broadly, this CO2 circulation technology can also be applied to not only our production facilities, but to manufacturing sites around the world, which will help with efforts to achieve carbon neutrality.

The plant represents the latest initiative in our broader commitment to sustainability, and our Reborn 21 focus areas of “Green” and “Peace of Mind.” With this, we continue to accelerate our efforts to achieve net-zero CO2 emissions, or carbon neutrality, by 2035.

For more details on the new plant, and our commitment to sustainability, follow this link: https://www.denso.com/global/en/news/newsroom/2021/20210407-g01/

Congratulations 2020 TPD Contest Winners & Participants!

The DIAM Technical Presentation Development (TPD) Contest is an opportunity for engineers to showcase their projects, while competing in front of a panel of judges for best overall presentation and insight into problem-solving, innovation, efficiency or other aspects of the project and process.

This year’s contest, held Nov. 19, was the first time the event was in a virtual format, adding a new level of challenge for participants. Please join us in giving a round of applause to all our participants for their hard work, preparation, and flexibility.

Congratulations to our winners!

First Place

Peter Atencio, PG3

Topic: Laser Welding – Optimization for your Application

Second Place

William Bickel, PG2

Topic: RU COM Development & Validation

Third Place

Eric Armbruster, PG3

Topic: Trailer Detection and Size Estimation Using Rear Corner Radar

Great job participants!

| Participant | Group | Topic |

| Dan McGrail | PG2 | Novel Design of a High Force Density Solenoid |

| Eric Armbruster | PG3 | Trailer Detection and Size Estimation Using Rear Corner Radar |

| Vincent Lee | PG2 | D2UC wipe quality issue |

| Christian Munte | PG3 | Mobility Platform Over the Air Update (OTA) |

| Matt Johnson | NAREC | Park Place: A new mobility opportunity takes a back seat to save $50M |

| Peter Atencio | PG3 | Laser Welding: Design Optimization For Your Application |

| William Bickel | PG2 | Alternator Design & Development for GMET6 Engine |

| Mike Pinger | PG1 | HVAC Heat Pickup |

| George Hadley | PG3 | RCCM Calibration Automation Development |

DENSO Creates First-of-its-Kind Factory-IoT Platform

DENSO has always been a leader in cutting edge technologies within the automotive industry. That’s why we’re thrilled to have launched our Factory-IoT platform that connects 130 production factories worldwide.

“When I was working on production technology on the manufacturing site, I sometimes felt that this procedure can be automated and the power of IoT should make it easier,” said Yuta Kuroda, a production engineer involved in the F-IoT platform creation. “So I participated in this project because I wanted to make it as efficient as possible with software and create new fun.”

After nearly two years of development, DENSO will now be able to enhance its collaboration abilities through data sharing with internal and external partners. Meanwhile, in-house engineers will be able to continuously improve the platform.

“At first, I felt a sense of urgency about the gap between the recent trends in software development and DENSO’s factory system development,” said Daisuke Nogi, another production engineer who helped create the F-IoT platform. “Therefore, we adopted software technologies that can be used outside the company, and in order to ensure that these technologies can evolve and continue to be used quickly even after the system has been built, we came to the conclusion with a sense of mission that we must secure human resources who are familiar with these technologies in parallel with the system construction.”

By connecting factories around the world in the cloud, the platform strengthens DENSO’s global production system, enables factories to respond immediately to production changes based on local demand, and allows production teams to conduct real-time analysis on the movement of workers and operation statuses of different facilities. In addition, technical engineers can use their own software to incorporate digital power into the platform’s physical improvement activities, which will further accelerate DENSO’s efficiency, quality and cost savings. For example, by linking various devices, it is possible to notify an operator of equipment abnormalities.

Learn more about this achievement and the DENSO associates who brought it to life: https://bit.ly/3lTiOPE

Manufacturing Month: Robotics

As part of our continued celebration of Manufacturing Month, we hosted a panel discussion this week on the always exciting topic of robotics and the role they play within DENSO.

Jody Freeman (Maryville, Tenn.), JD Phillips (Athens, Tenn), Jonathan Settlemyre (Maryville, Tenn.), and Stephen Doyle (Long Beach, Calif) sat down to chat (virtually) about how DENSO got its start in robotics more than 50 years ago and the impact robots have had on our company and the automotive industry as a whole. The team dove into topics like how robots are helping employees with their job all while increasing overall efficiency.

You can watch their conversation here: https://www.youtube.com/watch?v=xOJd0UhqYxA

We also hosted panelson Women in Manufacturing and Skilled Trades. To view either of these webinars, click the links below:

- Women in Manufacturing: https://www.youtube.com/watch?v=GbQk9wM2fN4

- Skilled Trades: https://www.youtube.com/watch?v=k8YTa6HamnY

Designing The Future Of Automated Driving

At DENSO, we are constantly working to drive the future of mobility and create innovative technology. In June, we hosted a virtual webinar called DENSO Tech Links Tokyo #7 with the theme “Human Drivers and AI — Automated Driving from the Viewpoint of Human Characteristics.”

This event featured DENSO associates who helped advanced automated driving technology and artificial intelligence (AI) research with the goal of implementing human characteristics. Associates Naoki Ito and Hiroshi Ino presented their work on this topic.

When it comes to the importance of human senses in automated driving Hiroshi Ino said, “We must clarify the specific senses and reproduce them by engineering in order to improve the system by integrating components of our five major businesses. This will be an important challenge in developing the next-generation system.”

If you are interested in learning more, follow the links below to view their work in detail: https://bit.ly/3fVtiKY / https://bit.ly/3aoMWhx

DENSO Spirit Spotlight: Sergio Pujols Helps DENSO Deliver Respirator Components in 25 Days

A spirit of foresight, credibility and collaboration – that is DENSO’s DNA and how team DENSO was able to help its customer deliver medical equipment components from concept to production in 25 days. Here’s a first-hand glimpse from Sergio Pujols, director of research and development at DENSO’s North American headquarters in Southfield, Michigan, and one of the project leaders that had DENSO producing respirator components for a customer to help protect health care workers fighting COVID-19.

How did you get involved with this project?

Our customer contacted me very late at night and said they had an idea to make a respirator to support our health care professionals fighting COVID-19 and wanted to know if DENSO could help. They sent us what I like to call a “napkin sketch” of a respirator concept utilizing automotive components, and a little over a week later we had a finalized design to be kicked-off for production, and new tools and an assembly line set up within weeks.

What can you say about the people who worked on this project?

I cannot say enough about the passion and dedication of this team. That first weekend, there were only a handful of us involved. But over time, a total of 200 DENSO associates worked on this project. Everyone came together to make this succeed – from global leadership and our customer to design and manufacturing engineers and production experts and even our security guards. Many of us were working 18-hour days. We were exhausted. But what really put it in perspective was reminding ourselves that people are out there dying from COVID-19 including the health care professionals who were putting their life at risk to help others. That made us push even harder.

What are you most proud of?

Two things. First, the commitment from our associates. I’ve always been proud to work at DENSO and after seeing how many of us came together to provide a solution to a critical problem during an intense situation, I’ve never been prouder. The level of commitment was astounding. And two, the support we received from top management. When we told our local and global leadership about the project, they essentially said, “Tell us what you need.” They were very engaged and passionate about what we were doing.

What was the biggest challenge?

The biggest challenge was time. As we spent time planning and preparing, doctors and nurses and other health care workers were still fighting and getting sick and even dying. We wanted to move fast. We had to work with our customer to design something and make it simple enough to manufacturer quickly. But we also had to ensure the product met DENSO’s standard of safety and quality. And, as you know, DENSO doesn’t design medical equipment. We followed our customer’s direction, but we also researched regulations and talked to hospital workers to understand what they needed.

How does it feel to be part of the fight against COVID-19?

It’s very humbling and it feels like it’s the least we can do. Every time you turn on the news or look at your phone, it’s all about the doctors and nurses not having PPE, and they still put their lives at risk. Knowing that, our entire team was eager to do something to help.

What would you suggest to someone who wants to support their local frontline workers?

If you want to support the fight against COVID-19 – stay home, if you’re able. That’s enough. If you want to do more, talk to your manager. There are many things happening at right now to help combat this virus.

New Innovation Center Reinforces Electrification Focus

At DENSO, we have a long history of producing products that push electrification technologies into the future. Last week, we doubled down on our promise to produce electrified automotive products, systems and technologies by opening an Electrification Innovation Center in Ajno, Aichi, Japan.

DENSO has long been a pioneer in hybrid and electric vehicle technology, and that tradition continues today. In 2018, it was a large part of our Second Founding, which focuses on key initiatives like electrification, automated driving, connected cars and other non-automotive business areas to prepare us for the future. This facility will help advance that commitment and rapidly transform new ideas into high-quality electrification products for our customers. Better yet, our associates will also create new energy conservation tech to help us reach our zero CO2 emissions goal at the new plant!

The Electrification Innovation Center will include:

- A development building to focus on developing and testing advanced production technologies

- A durability building to focus on reliability testing

- An outdoor track to test new products

- A production plant to support the quick establishment of a mass production line

To learn more about how this Electrification Innovation Center will support our commitment to a more sustainable future, click here.

DENSO a Top 100 Innovator According to PatentSight

In recognition of our commitment to creating the future of mobility, DENSO was named to PatentSight’s list of the Global Top 100 Digital Innovation Leaders. Out of the 100 global leaders listed, DENSO was ranked 22nd overall and eighth among global autonomous driving companies.

This recognition comes after several key initiatives we’ve implemented in the past year to support our Second Founding and Long-Term Policy 2030 – like opening R&D locations in Montréal, Plano, Texas and Seattle and creating our first Smart Mobility Ecosystem in Dublin, Ohio. These initiatives, and ultimately this recognition, would not be without the hard work and dedication from our associates.

“At DENSO, we strive to create technologies that promote safer roadways and communities, are cleaner for the environment and streamline transportation,” said DENSO’s Kenichiro Ito. “We are proud to be recognized as one of the world’s most innovative companies as we continue to change the way the world moves.”

To learn more about DENSO’s placement in PatentSight’s list of the Global Top 100 Digital Innovation Leaders, click here.

It’s Hard to Shield the DENSO Spirit

The COVID-19 pandemic is causing a shortage of medical supplies across the world, so when DENSO Manufacturing Tennessee (DMTN) reached out to Blount Memorial Hospital to see how we could help, the DENSO spirit took over.

“They are in dire need of face shields,” said Britt Autry, DMTN Vice President. “Our associates stepped up, designed a product, developed modeling and had a prototype within a day.”

Since Tuesday, March 24, a visor and shield have been designed and produced. After several modifications, a molding die started being developed for both parts and DENSO purchased straps to assemble the face shield.

Three days later, 30 DENSO face shield prototypes were donated to Blount Memorial Hospital. This week, an additional 75 prototypes are being sent to Fort Sanders Regional Medical Center and East Tennessee Children’s Hospital.

“We can’t thank DENSO enough,” said Alissa McMahon, BMH Director of Quality Management. “Everywhere you look, medical supplies are hard to come by. You are making us – and I’m sure eventually many other hospitals – extremely happy.”

Over the next two weeks, DMTN associates will install production cells in Building 204 to begin mass production. The line should be complete by April 8.

“This is DENSO spirit at is finest and fastest,” said Mark Moses, Intelligent Cockpit Director. “From idea, to design, to production, through safety and legal, it’s been a team effort and everyone should be extremely proud of what we can do together.”

DMTN’s Britt Autry demonstrates how the DENSO face shield is assembled to Blount Memorial Hospital’s Alissa McMahon.

Blount Memorial nurses show off the recently designed and 3D printed face shield prototypes DMTN will start producing in the next couple weeks. Pictured (L to R) are: Cara White, Holly King, Mariah Moore, Ari Small and Barbara Cave.

The DENSO face shield, to be produced in Building 204, says “Thank you for taking care of us!”

DMMI Receives $377,000 Energy Rebate

DENSO is letting our example shine by turning up the lights and turning down our energy usage! In December, DENSO Manufacturing Michigan, Inc. (DMMI) received a $377,737 rebate from Consumers Energy through their Business Energy Efficiency Program.

DMMI is one of the top 10 highest energy users for Consumers Energy in the State of Michigan due to the requirements of our compressed air systems and industrial brazing furnaces. This means we must continuously look for ways to save energy to reduce our environmental impact and save money. In recent years, multiple lighting and energy saving projects have been implemented in the parking lot and boiler areas. This latest rebate was for full plant lighting replacement and advanced controls such as those used for controlling light activation on motion sensors in the scrap dock area.

Induction lights throughout the plant were replaced with LED lights featuring wireless control capabilities. The plant is now much, much brighter, with LED lights that can produce more than three times brighter light while using less energy. In addition, the Facilities department maintains a computerized system that controls the lights within an overall Facilities Management System.

The cost and environmental impact is tremendous—280 tons of CO2 emissions per year are saved from the project, and the amount of energy saved is equivalent to the annual electricity usage of 144 homes.

The monetary return from the project exceeded our expectations by over $90,000. The rebate will allow the Facilities department to help offset utility expenses from 2019 fiscal year.

Associates can play a key role in making improvements by looking for energy waste in their own areas. If you see an area for improvement or have an idea, please speak up!

Highlights from 2019 North America Quality Circle Competition

Congratulations to winners and all those who participated in DENSO’s 2019 North America Quality Circle Competition!

QR Code Innovation: The Future Has Just Begun

DENSO’s celebrating 25 years of QR Code innovation. The QR Code (abbreviated from Quick Response Code) is a matrix barcode invented in 1994 by DENSO WAVE. Its purpose was to track manufacturing; it was designed to allow high-speed component scanning, but now, QR codes are used in a much broader context, such as payment, flight check-in and more.

QR codes made our life a bit more convenient. DENSO is dedicated to continue the development of technologies that can enrich our life.

How will the QR Code change over the next 25 years? Read Q&A with QR Code developer Hara Masahiro to find out.

Looking back 25 years on from the QR Code’s development, did you imagine the extent to which it is currently used?

I thought I’d made a good code in my own way, so I believed it might become popular in industrial applications. But I hadn’t imagined a situation where ordinary people would use it this much, and that the QR Code would be visible throughout cities. In particular, I never thought the QR Code design would be used as a fashion statement in clothes and accessories, or that you would be able to buy goods using QR Codes.

How do you think the QR Code will be used in the future?

One thing I was thinking about partway through the QR Code’s development was to “encode a database itself, and use it offline.” It was often used this way in the initial stages, but this gradually decreased as the network developed. However, it might be worth revisiting as a way of avoiding social problems given it’s sometimes not possible to exchange data in the aftermath of a major disaster, when power outages happen and telecommunications infrastructure has been damaged. In addition, regarding the issue of database leaks of personal information, cases of recording a database in a QR Code with security capabilities and storing it privately will also increase in the future. With that in mind, I will work to develop a QR Code with even more advanced security so people can use it with peace of mind.

Message to future researchers:

Being able to have people around the world use something you developed is an engineer’s dream. I want everyone to try developing something new. When you do that, it’s natural that you will experience some failures since there is no precedent. So go ahead and do what you want to do without worrying about whether you will succeed. Within the failures will be a variety of useful information, and by observing and analyzing that, you will find clues to your next step. I think that having the ability to learn from such mistakes, and use the mistakes to develop something new and innovative, generates the energy to take on new challenges. The accumulation of that leads to creativity. I think that learning from mistakes through trial and error is the best shortcut to achieving success of real value.

Learn more about the QR Code at https://www.denso-wave.com/qr2019/en/

Who is DENSO ADC?

This month, DENSO’s celebrating 25 years of QR Code innovation. The QR Code (abbreviated from Quick Response Code) is a matrix barcode invented in 1994 by DENSO WAVE. Its purpose was to track manufacturing; it was designed to allow high-speed component scanning, but now, QR codes are used in a much broader context, such as payment, flight check-in and more.

So, who is DENSO ADC? Check out the video below to learn more about the teams behind our QR Code innovation:

QR codes made our life a bit more convenient. DENSO is dedicated to continue the development of technologies that can enrich our life.

The QR Journey

This month, DENSO’s celebrating 25 years of QR Code innovation. The QR Code (abbreviated from Quick Response Code) is a matrix barcode invented in 1994 by DENSO WAVE. Its purpose was to track manufacturing; it was designed to allow high-speed component scanning, but now, QR codes are used in a much broader context, such as payment, flight check-in and more.

QR codes made our life a bit more convenient. DENSO is dedicated to continue the development of technologies that can enrich our life.

See what you can do with the QR Code in The QR Journey video below!

Next CoA HVAC Line Starts Up with World-Class Recognition

The next CoA (common, compact, collaborative) HVAC line started production at DENSO’s manufacturing facility in Battle Creek on July 22. Although it is the second CoA line, associates throughout the region made sure it is a project filled with firsts.

“The goal for this project was localization, and it was a huge development opportunity,” said Mike Curbey, HVAC Engineering Manager. “This is the first CoA line in the world to be built 100% locally.”

CoA2 is also the first HVAC line with IoT (Internet of Things) connectivity and the first line at DENSO in Battle Creek with a collaborative robot.

Senior Engineering Technician Eric Paulson said that the team at DENSO in Battle Creek worked closely with machine builders at DENSO in Maryville, Tennessee on the localization effort.

“One of our biggest challenges was helping the machine builders understand our needs exactly,” Eric said. “We were starting with something originally designed in Japan and asking the DENSO Tennessee team to build it to the specifications of our local needs in Michigan. We just had to figure all of that out.”

The new line will produce HVACs for three Subaru models produced in the United States. Subaru of Indiana Automotive (SIA) has already recognized the line as a world-class process.

Congratulations to everyone that made the HVAC Auto Line 2 a reality over the last two years. This is a big step towards DENSO’s future!

Celebrating 25 Years of the QR Code, a DENSO Innovation!

Did you know that the QR Codes were originally developed by DENSO? Today marks the 25th anniversary of the creation of QR Codes, the ongoing development and distribution of which are now the responsibility of DENSO WAVE Inc.

QR Codes were originally developed to make manufacturing operations more efficient. However, DENSO decided to make the technology license-free in order to encourage their use by as many people as possible, and QR Codes have since spread to a huge range of fields.

With the growth of cashless payment systems, QR Codes are garnering more attention than ever, making this the ideal time to tell family and friends about this versatile DENSO invention!

For more information on QR Codes, visit the DENSO WAVE website at: https://www.denso-wave.com/en/system/qr/

Emilee’s Core: Creativity

DENSO was Emilee’s first job out of college. Nine years later – she’s still here getting things done, working in the Total Industrial Engineering (TIE) group in Athens, Tennessee. For Emilee, creativity is at the core of problem-solving and dealing with uncertainty.

From earning her Bachelor of Science in Industrial and Systems Engineering at the University of Tennessee, to navigating her career path at DENSO, Emilee has long understood it takes creativity to solve difficult problems, deliver quality work and design innovative solutions.

“One of my first TIE projects at DENSO involved a machine modification. Before kaizen (improvement), there were many inefficiencies in the process. I used creativity to re-design this machine by building a mock model completely out of scrap cardboard. By using what was readily available, I quickly constructed a prototype that we could use in cross-functional team meetings. The model was detailed to the point where we could simulate the process flow with associates to get their feedback on the standard hand motions and product placement. This activity made it possible for us to understand the footprint requirements, estimate the cycle time and improve ergonomics before the final machine was constructed. We were able to save DENSO time and money by focusing on an efficient line from the design phase.

The future will require all of us to be innovative and work together. Don’t be afraid of your wild ideas. Speak up, be ambitious and work together to enhance the visions and dreams around you.”

– Emilee Davis, Total Industrial Engineering, Athens, TN

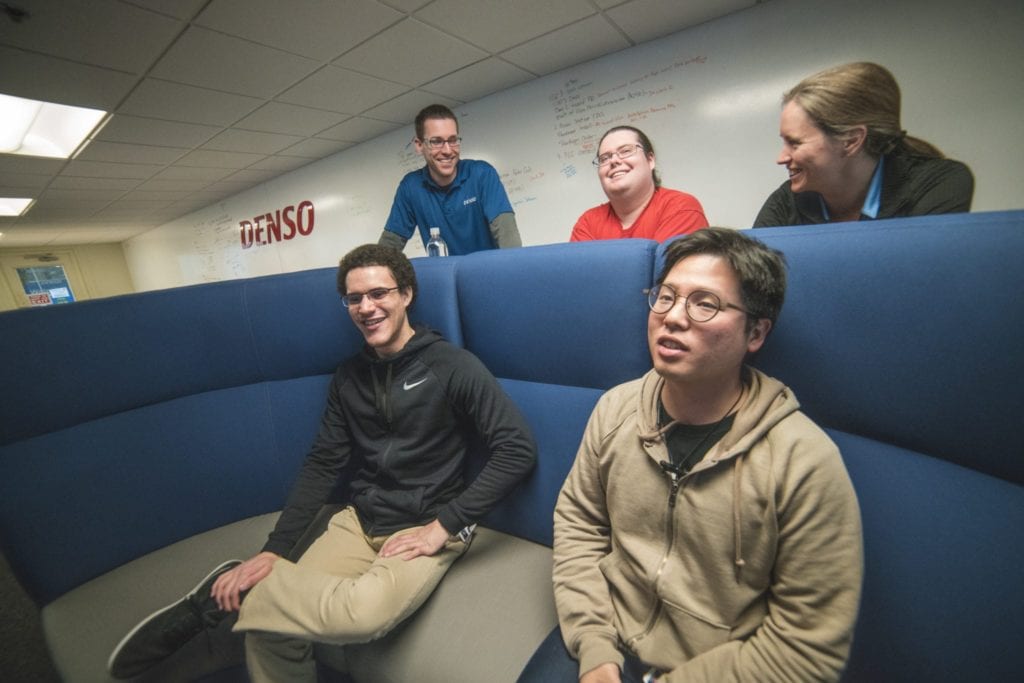

Prototyping the Modern Office

Every day at DENSO, someone is making a prototype for an automotive part. Now up in the North Office, the Internet of Things (IoT) Team is prototyping something drastically different—a modern office environment.

The IoT office space is filled with big blue couches, circular desks, bright bold colors and a whiteboard that spans the entire office. This prototype is based on one central concept—collaboration.

“We want to create an environment that encourages discussion and openness,” said Teresa Hansen, IoT Section Leader. “This helps encourage learning between senior staff and new staff.

Most DENSO office areas are a sea of grey or beige, so the IoT office stands out. But modern office environments are now commonly designed with color and collaboration in mind.

“I like the color scheme and all the little nooks where you can meet up,” IoT Programmer Nam Le said. “We couldn’t separate ourselves for focused time if we needed the seclusion before. Now the whole room is very flexible.”

As the war for talent gets more and more intense, job seekers are coming to expect modern, collaborative office environments. But even longtime associates like Advanced Software Developer Joe Delbridge love the IoT prototype office.

“It’s the first time in my 21 years that I have seen an office change this drastic… and it’s a great change.”

The door to the IoT office space is locked for security reasons, but Teresa said that this doesn’t mean associates aren’t welcome. In fact, anyone can stop by to take a look around, or bring their laptop along to try out one of the collaboration spaces.

“We want people to see this and want to be a part of it. We want this to show that we’re changing the game at DENSO.”

Contact Teresa or a member of the IoT team with questions or to set up a time.

A Look at DENSO’s Strategic Partnerships

At the 2018 Consumer Electronics Show (CES), we talked to Ridecell & ThinCI about our strategic partnerships & business opportunities. Our Senior Vice President of Engineering Bill Foy, and Tony Cannestra, director of Corporate Ventures, also weigh-in on why DENSO is partnering up.

You’ll hear more about our partnerships with these companies & others in months to come—stay tuned!

Leadership Perspectives – DENSO Venture Capital Investments

DENSO’s Silicon Valley (Calif.) office opened in 2011 to focus on emerging areas of advanced software technologies and to pursue venture capital investments.

Bill Foy, senior vice president of Engineering at DENSO, and Tony Cannestra, director of Corporate Ventures, talk about why venture capital is an important, strategic move for DENSO.

Not only does investing in entrepreneurs and startups allow us to strengthen and grow our core automotive business, it allows us to branch out into new, emerging technology and non-automotive business areas. It also pushes DENSO to think differently.

Learn more from Bill and Tony in the video below:

DENSO Bot Competes In Battle Of The CES Robot Baristas

Did you know DENSO featured a line of robots at CES in 2017? DENSO’s COBOTTA robots showed CES guests what future, day-to-day life could be like if people and robots collaborated more. For instance, one of our robots acted as a “Barista-bot” that brewed and served coffee to our DENSO booth visitors on the spot!

A few other companies also showcased their own Barista-bots at CES. Wondering how DENSO’s robot barista fared against Bosch and Aubo? Click here to find out which bot made the best cup of joe.

More About Our DENSO Bots

DENSO has been a leader in manufacturing automation, including the design and manufacturing of industrial robot arms, since the 1960’s. Now, we use more than 17,000 of our own robots at DENSO manufacturing facilities across the globe. And, more than 85,000 DENSO robots are used for precision assembly, manufacturing, product testing and quality assurance by other companies worldwide.