A Commitment to Eliminate Customer Pain Points

How teams across DENSO unite to breakdown silos and achieve best in class product quality

Come into work, do your job, keep your head down – this is the routine many of us find ourselves living every day. One team wanted to do more. They decided to tackle one of their customer’s biggest pain points – a warranty issue.

For years, GM’s largest warranty spend category has been with engine management systems, of which DENSO provides the fuel injector. Many times DENSO has gone through its necessary process to test and check that our part isn’t causing the bigger system issues, and each time, everything checked out – no problem. Meanwhile, GM continues to pay the warranty costs, and issues continue to creep up.

This didn’t sit well with the DENSO team. With values of foresight, credibility and collaboration ingrained in their way of working, they needed to dig into this issue before it put a strain on the customer relationship, DENSO’s reputation, or our financial situation.

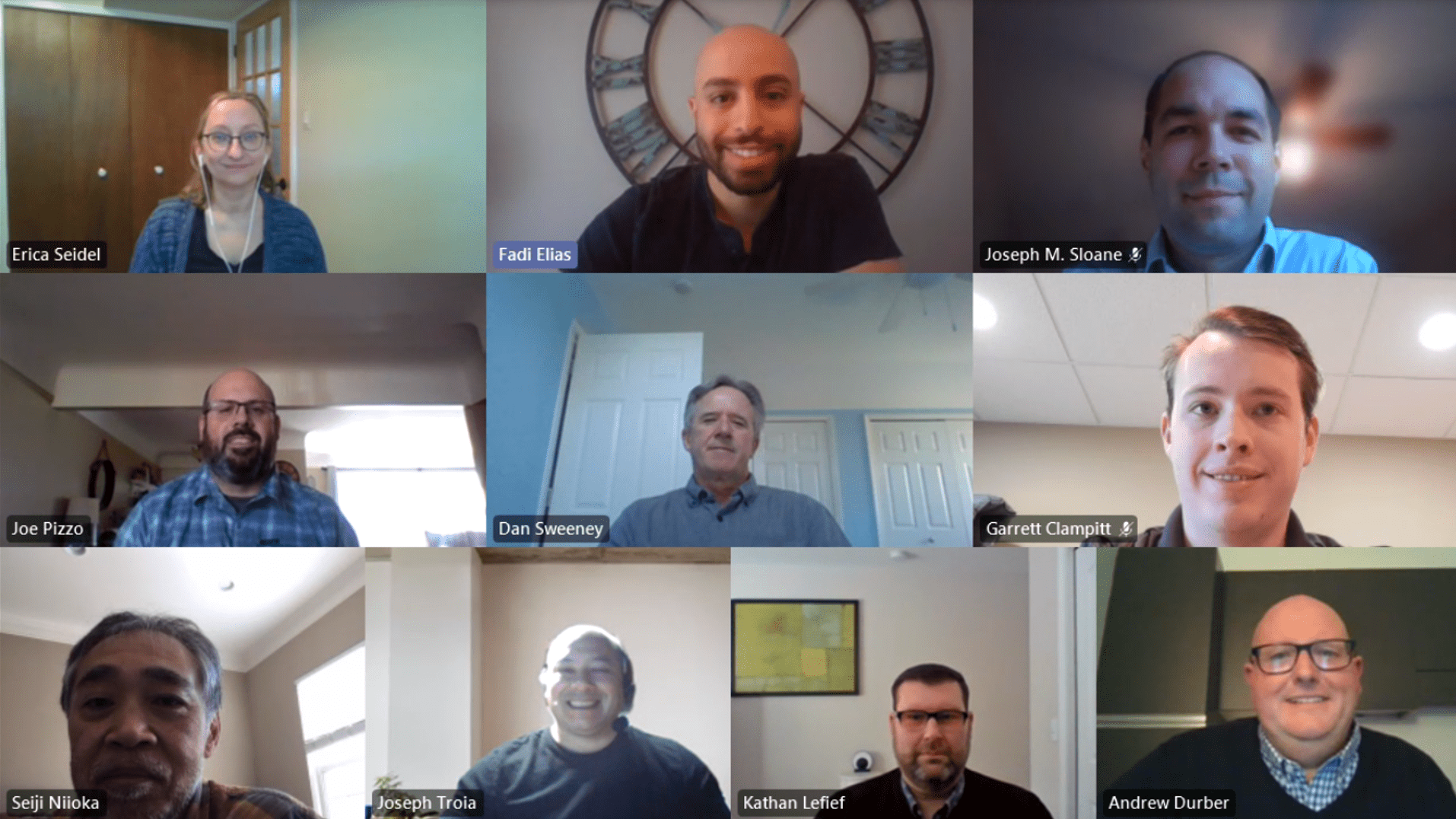

The team formed the Warranty Initiative – a collaborative team across DENSO focused on partnering with the customer to find the root cause of the warranty issue.

“We don’t know where the blame for this issue lies, and it doesn’t matter. We’re taking on the issue either way in order to be a better partner to our customer. The only way we can achieve best-in-class quality for our products is to look at pain points, have honest discussions with each other and our customer, and to recognize when and where we’re not succeeding. Our products are only as successful as the systems they’re a part of, and we want them to be the best,” said Joseph Sloane, Manager of DENSO’s Service Engineering team.

Forming the Warranty Initiative team has been all about breaking down silos and looking at the issue from the customer’s point of view. To do this, the DENSO team involved all those who contribute to the success of the product, including DENSO Sales, Engineering, Quality, and Production.

“It was important for everyone to be involved, and passionate about the same vision – to achieve best-in-class quality – and the same goal – to find the root cause of this warranty issue,” said Fadi Eias, Manager of Engineering.

Once they were on the same page, they initiated a meeting with the customer to better understand their struggle points, share their commitment to finding the root cause, and to ask the customer to be a partner in this process.

“Taking a step back and seeing the customer pain points was our first step – this includes our internal DENSO teams, our OE customer, and also the end users. No one needs the added stress of taking their vehicle to a dealership right now – that’s something we can all relate to. So, what can we do to make sure our products are the best quality and don’t contribute to a warranty claim,” said Joseph.

The project has kicked off and the team is currently working on what they set out to do. Meanwhile, their passion and approach are turning heads, motivating other DENSO teams to take a similar approach in addressing their OE customer warranty pain points.

“We’re getting back to the basics. It seems like common sense, but DENSO has grown so much, so quickly over the past decade, and we’ve gotten away from what makes us unique, what makes our products and teams the best,” said Vincent Celli, Manager of DENSO’s Service Engineering team. “It’s not enough to say ‘our product didn’t cause the issue, it’s not our problem.’ That’s not putting yourself in the customer’s shoes. We’re shifting this mindset so we can get back to best-in-class quality for our customers and end users.”

Learn More

Click here to watch a video of Joseph and Fadi introducing the Warranty Initiative.

Share your Story

DENSO globally introduced Reborn 21, an initiative to help guide all of our efforts on actions that will help the company survive and thrive this year and beyond. Learn more about Reborn 21 and how teams are rebuilding quality and changing the way we work, here (password: denso2020). All associates play an important role in helping the company survive and thrive – to share your story or ideas, email Communications@na.denso.com.

Comments