Search by Topic

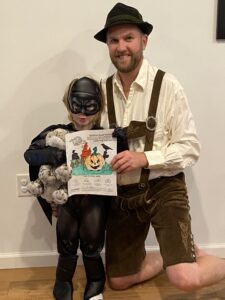

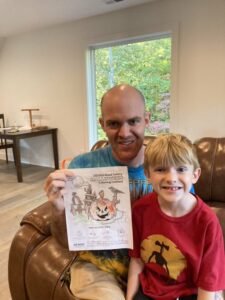

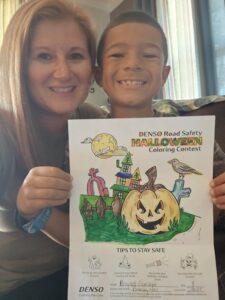

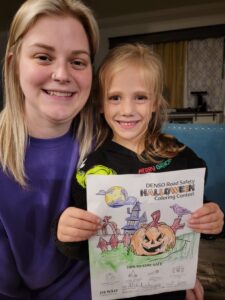

2023 Halloween Coloring Contest

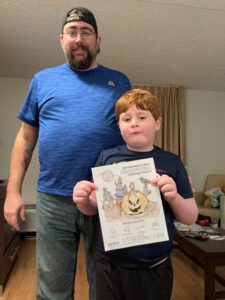

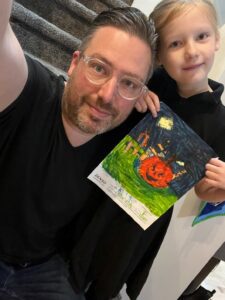

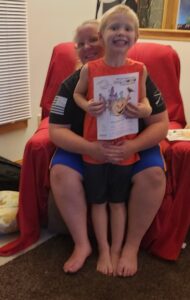

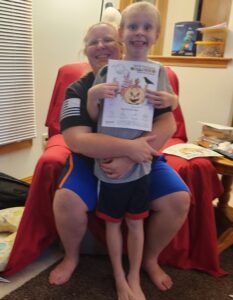

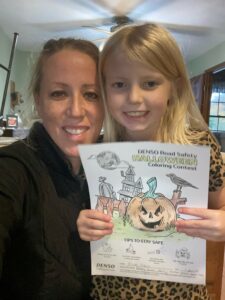

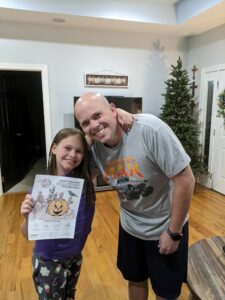

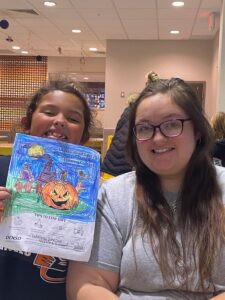

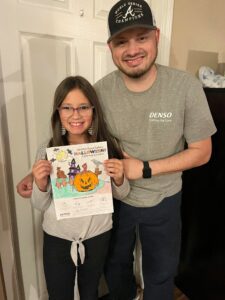

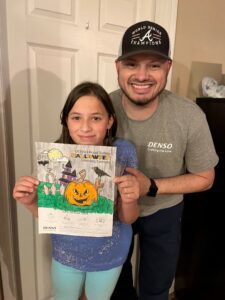

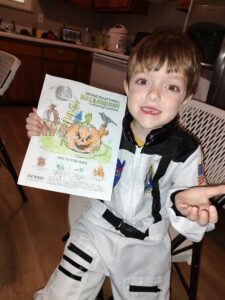

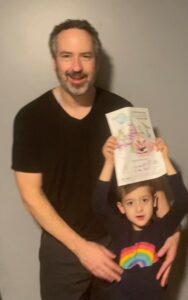

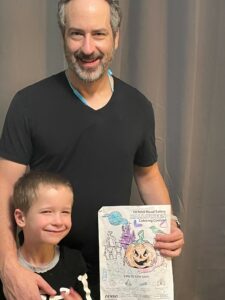

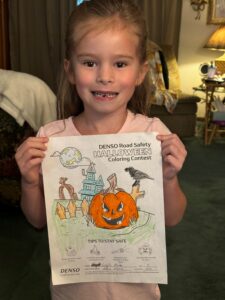

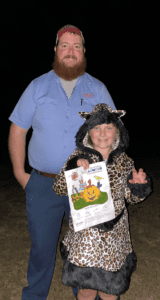

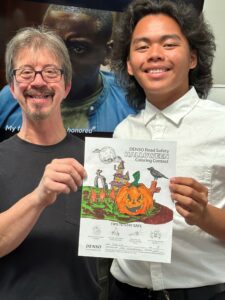

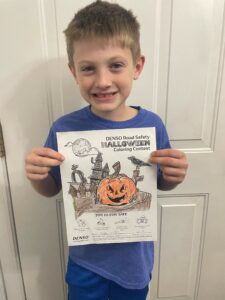

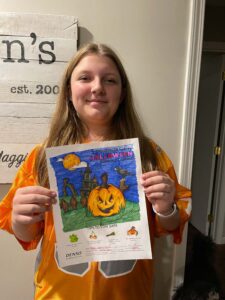

Congratulations to the winners of the Halloween Road Safety Coloring Contest!

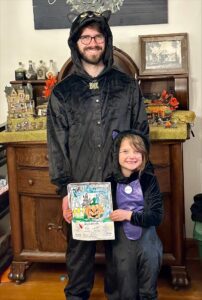

Alexis Rutherford, Kenneth Rutherford’s daughter (Maryville, TN)

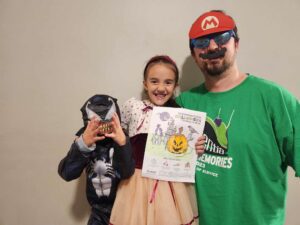

Alivia Syck, Nicholas Syck daughter (Battle Creek, MI)

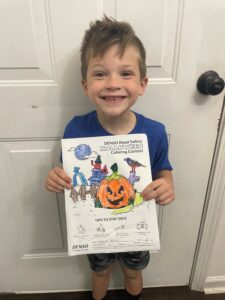

Michael Huber, Derek Huber’s son (Athens, TN)

Check out the entries below:

GM Supplier Discounts Available, June 1-July 5, 2023

DENSO associates can enjoy GM employee pricing from June 1 – July 5, 2023 toward the purchase or lease of one (1) eligible new Chevrolet, Buick, GMC or Cadillac Vehicle.

WHO IS ELIGIBLE

Current/active DENSO associates at U.S. group company locations

HOW TO ACCESS THE OFFER

- Current/active DENSO associates will need to “sign-in/register” to their individual GM Supplier Discount Program accounts at www.gmsupplierdiscount.com/soty (website available on June 1)

- When creating a new account, you will need DENSO’s unique company code: 843043

- Select the offer from the program menu “+2022 Supplier of the Year Employee Discount Pricing”

- Authorization number must be obtained between June 1 – July 5, 2023. The offer for employee pricing will not be available before June 1 or after July 5, 2023.

What to provide to a participating dealer:

- Inform dealer of the Supplier of the Year Employee Discount offer before taking delivery

- Bring your authorization code

- Bring your Driver’s License, Company ID Badge or current paystub with earnings information redacted

The company code (843043), program flyer, and handout provide the necessary information to setup your GM Supplier Discount account and receive your 2022 Supplier of the Year Employee Discount Pricing.

THANK YOU ASSOCIATES!

This offer is available to DENSO for achieving GM’s 2022 Supplier of the Year Award. The Supplier of the Year award recognizes distinguished global suppliers that exceed GM’s requirements, in turn providing GM customers with innovative technologies and among the highest quality in the automotive industry. Thank you to all our associates for this outstanding accomplishment!

DIAM Associate Appreciation Event – Maps

Click on the link below to view the map.

Associate Event Map

Tech Center Tour & Tech Showcase

DN2-1

DN2-2

DN3-1

DN3-2

DN4-1

Autonomous Drive Route

If you signed-up to ride, please check-in where it says “Autonomous Vehicle Ride Experience”, between buildings DN2 and DN3.

Global President Arima Visit – Meeting Locations

Click here for directions on how to get to the Special Director’s & Above Meeting Location

Kronos Outage – FAQs

Updated: 01/11/22

As you know, Kronos has been hit by a cyber-attack and is currently unavailable. Kronos is used for timekeeping (hours worked, PTO, leave, etc.) at DMAR, DMAT, DMTN, DLNT, DMCN, DSCN, and all DMMI and DPAM locations.

This FAQ document will answer questions as we navigate the Kronos outage together.

Please note: these FAQs are for all impacted companies EXCEPT for DPAM. There are some slight differences with DPAM Payroll.

Work with your location’s HR/Team Member Solutions/Associate Relations team to submit and receive answers to any questions.

Updates

- 1/11/22 > EPIQS/DOMO FAQ 17 updated

- 12/22/21 > Homebase FAQ 8-9 added

- 12/22/21 > EPIQS/DOMO FAQ 12-23 added

- 12/21/21 > Homebase FAQ 1-7 added

- 12/21/21 > EPIQS/DOMO FAQ 1-11 added

Homebase FAQ

1) Which associates should be using Homebase? |

|||||

| Only Team Leaders and Non-Exempt associates should use Homebase to record their clock in/out times. | |||||

2) Can an associate use the manual time sheet to record their time, instead of Homebase? |

|||||

| All Team Leaders and non-exempt associates are strongly encouraged to use Homebase to track their clock in/out times. This will help ensure accuracy and save time spent manually inputting the data into EPIQS. A manual time sheet should only be used as a last resort to track clock in/out times. | |||||

3) I’m a specialist—do I need to register in Homebase? |

|||||

| No. All non-Team Leader exempt associates (specialist, engineers, etc.) should submit PTO and other time off requests to their leader using the manual time sheet. Your leader will enter that information into EPIQS. | |||||

4) How do Team Leaders and non-exempt associates register for Homebase? |

|||||

| If you have not already received an invitation to join Homebase by either text or email, you can click here to submit your information. Within a few hours, you will be sent a registration email or text and will create an account in Homebase using either an internet browser or the mobile app. | |||||

5) How do I input PTO or other leave in Homebase? |

|||||

| Associates should record PTO requests or other leave using the manual time sheet. DO NOT use Homebase to record/request PTO or leave. | |||||

6) I’m being asked in Homebase about my availability. What should I do? |

|||||

| Ignore that option. It is an additional feature of Homebase that DENSO is not using. | |||||

7) Should associates approve their time in Homebase? |

|||||

| That feature is not available in Homebase. The application only records your time in and time out. Your Team Leader will then review and approve your hours in EPIQS. | |||||

|

EPQIS / DOMO FAQ

1) How are the hours in EPIQS populated? |

| If non-exempt associates and Team Leaders are using Homebase, the data will be uploaded to EPIQS every 15 minutes. Otherwise, non-exempt associates will start with zero hours each day and exempt associates with eight hours. |

2) What do I use EPIQS / DOMO for? |

| These two pieces of software are collecting data from Homebase. The DOMO Time and Attendance dashboard is used by leaders to view associate work hours. Links in this dashboard will pull up an EPIQS editor to update associate hours. The editor can only be accessed via the links in DOMO. Logging into both systems is required to make changes. Leaders will review, correct and approve all hours through EPIQS. Please contact your TMS/AR representative if you do not have access. |

3) There are Team Leaders and Managers on PTO during the holidays. How many levels can approve an associate’s time? |

| Three levels of an associate’s leadership chain can input and approve hours. |

4) If an associate elects to only use the manual time sheet, how often should a leader input that data into EPIQS? |

| It is critical that the data is updated to accurately compensate our associates. We know leaders are extremely busy, but this should be a priority and built into your daily work. Do not wait until multiple days are accrued before reviewing for approval. |

5) How do we code overtime? |

| If additional time is added directly into EPIQS, then the totals hours would need to be reviewed and the overtime pay code selected as needed. |

6) We have associates working four 10 hour days. How should we code day five? |

| As long as the total hours is 40 hours for the four days, then the fifth should have zero hours and not need a code. |

7) How long does it take for an associate’s Homebase clock in/out times to be available in EPIQS? |

| Please allow 15 minutes for the Homebase data to be uploaded into EPIQS/DOMO. |

8) How do associates record no pay no penalty? |

| No Pay No Penalty has been added as a pay code in EPIQS. |

9) How do you code Flex and Extended Flex? |

| Flex and Extended Flex codes are being added into the pay code drop down. |

10) Which browsers work best with EPIQS? |

|||||||||||||||||||||||||||||||||||

| EPIQS works best with Chrome and Edge browsers. | |||||||||||||||||||||||||||||||||||

11) What if I cannot access DOMO? |

|||||||||||||||||||||||||||||||||||

First, try resetting your DOMO password. Both the EPIQS and DOMO links can be found on the DENSO Portal. Please contact TMS/AR if you cannot log in.

|

Homebase Timekeeping System

As you know, Kronos has been hit by a cyber attack and is currently unavailable. Kronos is used for timekeeping (hours worked, PTO, leave, etc.) at DMAR, DMAT, DMTN, DLNT, DMCN, DSCN, and all DMMI and DPAM locations.

Associates do not need to reset their password – Kronos is unavailable. Unfortunately, we are not sure when Kronos will have the situation resolved for the global companies, including DENSO, that use their timekeeping system.

FREQUENTLY ASKED QUESTIONS

TEMPORARY SYSTEM

In response to the Kronos issue, DENSO is implementing a temporary system for timekeeping called Homebase. Homebase is a simple software application that allows non-exempt associates and team leaders to enter their time clock in/out.

- This temporary process is for non-exempt associates and team leaders only. This includes office non-exempt associates.

- Managers of Exempt associates will need to enter their associates’ exceptions (PTO, leave) into EPIQS. Exempt associates should notify their manager of exceptions.

- Temporary associates at DMMI will need to use the attached paper form to track their time, and their managers will have to enter their time into EPIQS.

- Temporary associates at all other impacted sites will follow established process through their agency.

RECORD YOUR TIME

There are 2 methods for non-exempt and team leaders to capture time worked, starting Monday, Dec. 20.

1) Homebase App or Web:

- Notification from Homebase: If you have an email (personal or work) or cell number saved in Oracle, you may have received a link to join the Homebase system. The email will come from <info@joinhomebase.com>. This is a legitimate email. Please check your phone or email (personal and/or work) to see if you received this.

- If you deleted the text, you can follow the instructions attached to download the Homebase app.

- If you deleted the email, search their trash for an email from Homebase.

- Request Access: If you did not receive an email from Homebase, click here to go to Microsoft Forms. From here, you will have to enter the following information in order to request access to Homebase:

- Name

- Company Location

- Associate ID/Clock Number

- Email/Cell Phone

- Email will give you access to a web version of Homebase or mobile app. The email will come from <info@joinhomebase.com>. This is a legitimate email.

- Cell will give you a link to download the Homebase Mobile App

- You can enter either one, or both.

Within a few hours, you will receive either link via email or text via cell to access Homebase web or mobile app.

You must receive an email or text notification from Homebase in order to access the system.

If you are having issues logging into Homebase, contact Team Member Solutions (Associate Relations).

2) Paper Time Tracking:

If you do not want to use Homebase, you can continue to use a paper tracking form – attached. Associates will have to sign-off on the paper form and give to their leader for approval.

DOCUMENTS

- Instructions on How to Install the Homebase App

- If you have not received a Homebase email or text for the app, you will have to enter your information here in order to register for access to the app.

- Instructions on How to Use Homebase

- Paper Time Tracking Form

All of these documents are available from your Chain of Command, Team Member Solutions (Associate Relations), and Accounting. They are also available on DENSO Mobile, DENSO Online, and DENSO Portal.

We understand this is a difficult situation for everyone. We have teams working around the clock to put a temporary solution in place. But, we can get through it together if we collaborate and support each other. Thank you again for your cooperation and patience.

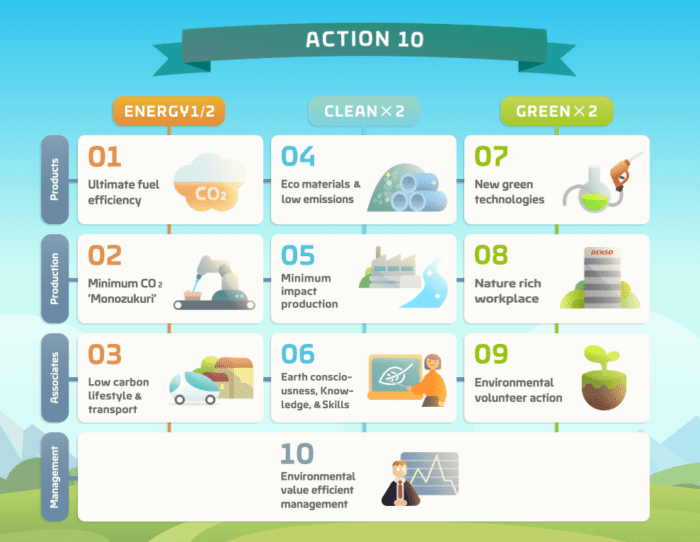

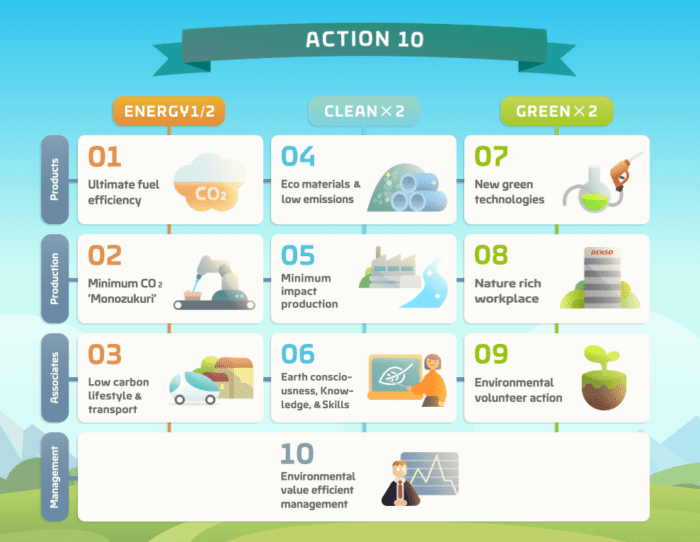

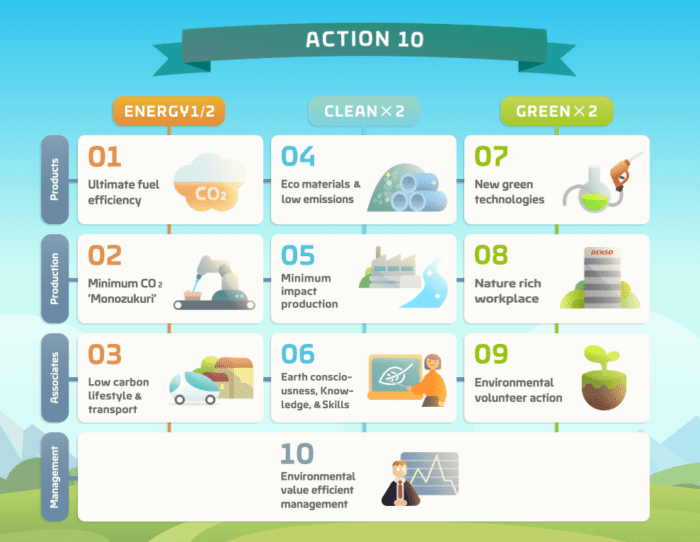

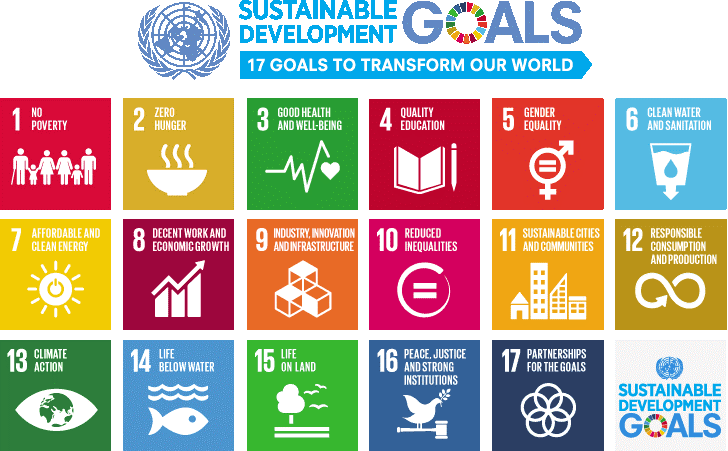

DENSO’s Commitment & Actions for Earth Day

DENSO has a long-time commitment to the environment as demonstrated through our 20 years of EcoVision and recently announced target to become Carbon Neutral.

This year, for the 51st Earth Day, DENSO encourages all associates to take action to help the environment. Whether small or big changes, every action is important.

5 Ways you Can Help the Earth:

- Bring a bag with you to pick up trash while enjoying the outdoors

- Reduce your use of single-use plastics (https://www.earthday.org/plastic-pollution-calculator-2/)

- Compost food waste

- Change your paper bills to online billing. You’ll be saving trees and the fuel it takes to deliver your bills by truck

- Become a citizen scientist with your cellphone (https://www.earthday.org/campaign/global-earth-challenge/)

Click here for more tips and actions that help the Earth.

Green DENSO Activities

Shoutout to our DENSO associates across North America who are organizing events for environmental awareness and action!

DENSO Manufacturing Michigan

The Environmental Department team is at main entrances this morning with pledges regarding water, waste and energy/greenhouse gases – associates can sign to pledge their commitment to help improve our environment.

DMMI is also supporting two (2) volunteer events, encouraging associates to help out in the local community: City of Battle Creek Linear Park Clean-up on April 24, and Adopt-a-Highway Volunteer Clean-up which was held April 17.

DENSO Manufacturing Canada

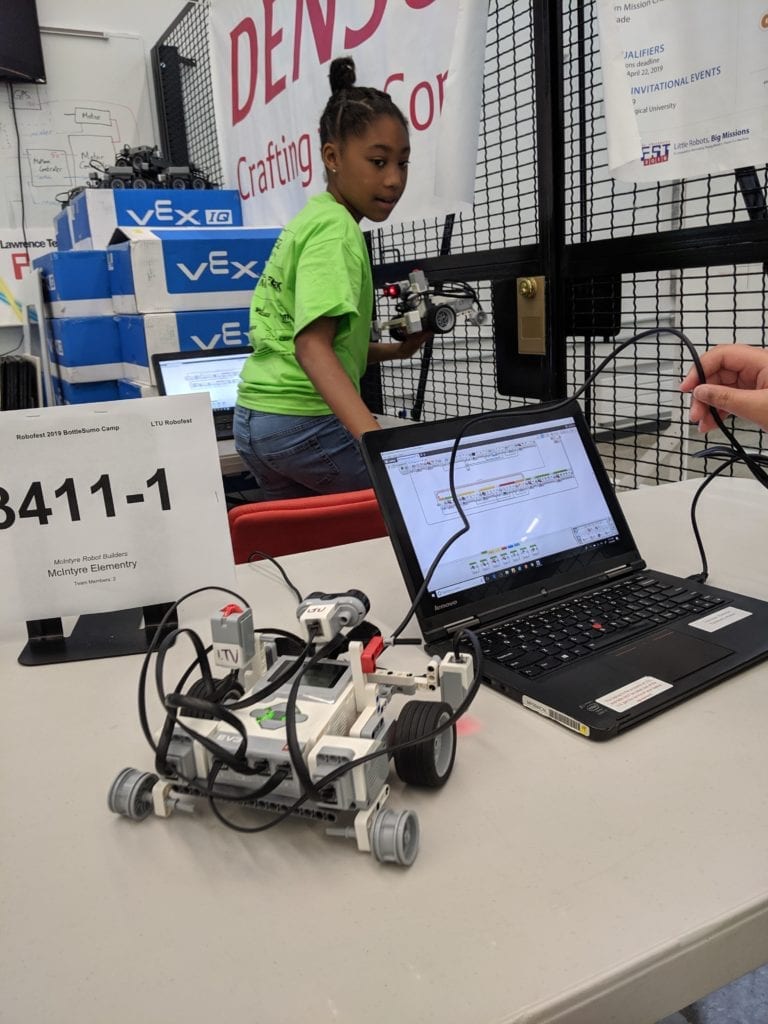

DMCN is hosting a challenge for DENSO families, challenging kids to build a DENSO robot using only recycled materials from home. The Robot Building Contest runs through April 28.

Share what you’re doing!

Let us know in the Comments how you’re spreading environmental awareness or taking action to help our Earth.

DENSO Robotics Donates to UT Chattanooga

The University of Tennessee at Chattanooga (UTC) officially opened its new Mechatronics Lab on March 31. DENSO Robotics was on hand to donate three robots and software to advance education in this rapidly growing engineering field.

“We need more students interested in engineering and technology,” said National Sales Manager David Robers, DENSO Robotics. “This is the perfect way for us to encourage that and help labs like these grow the next generation of engineers.”

Mechatronics combines electrical and mechanical engineering degrees. Robotic design, programming and maintenance are key study areas of the program.

“The industry is changing from traditional manufacturing to an industry 4.0 environment,” said Dean Daniel Pack, UTC College of Engineering and Computer Science. “Mechatronics is a new discipline that teaches students to prepare for those types of careers.”

DENSO Robotics donated two COBOTTAs for the lab, as well as the latest high-speed VMB six-axis robot. A COBOTTA is a human-friendly, compact and collaborative six-axis robot that can be taken anywhere and automate tasks quickly.

“Having these labs integrates all aspects of engineering and you can see how it all relates to each other,” said Erin Watson, mechatronics senior. “We definitely need relationships like what we have with DENSO Robotics, and we can’t thank them enough.”

DENSO Robotics plans to donate more than a dozen robots in 2021 to community tech and state university partners to excite future engineers and highlight advancements with the technology.

Learn more about DENSO Robotics here. And to see our roundup of the lab’s grand opening, watch this video.

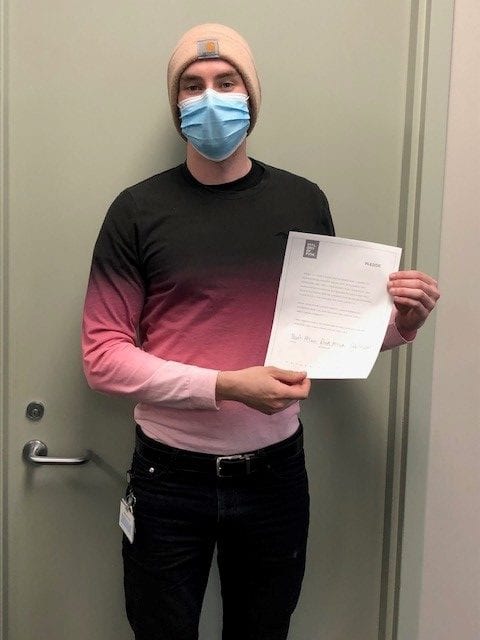

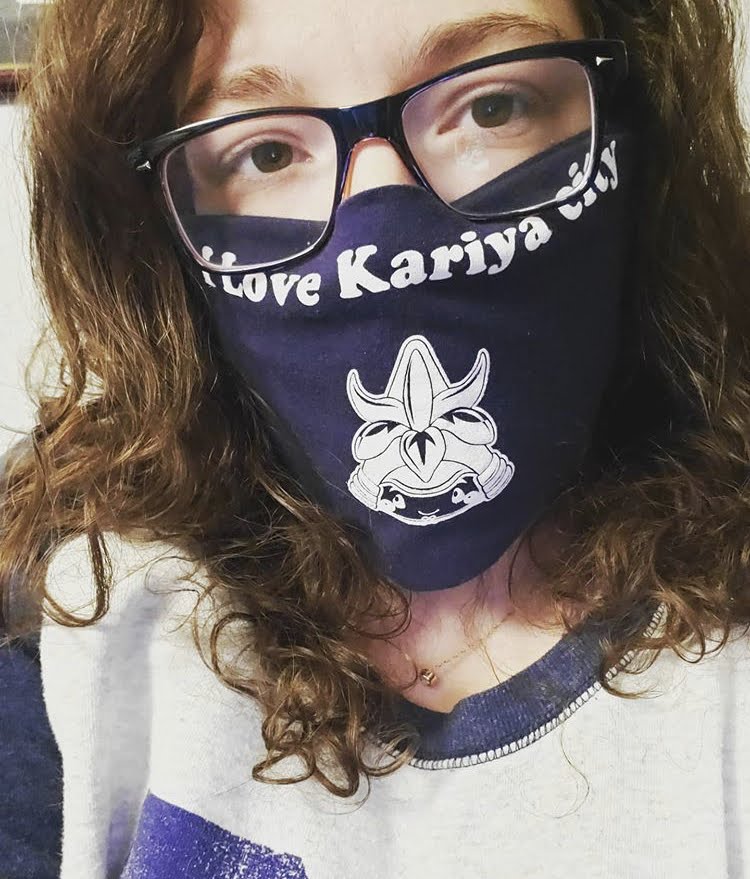

DMCN Wears Pink to Raise Awareness to Stop Bullying

Associates at our DENSO Manufacturing Canada facility proudly wore pink on April 14 to raise awareness to end bullying, discrimination, homophobia and transphobia.

Associates also signed a pledge to share their commitment to the cause.

Learn more about the International Day of Pink at www.dayofpink.org/

Tenured Employee Spotlight: Linda Huber

Some of our employees have watched us grow from the ground up. Linda Huber, Senior Talent Management Consultant at our Southfield, Mich. facility, started her career with us 1985 – that was before we had even built our North American plants! Here’s what Linda had to say about her experience:

“I started my career with DENSO 35 years ago – and I had no idea who Nippondenso was! When I started with the company, there were no more than 30 associates, and no North American plants. Now, we have more than 1,600 employees on our campus, and manufacturing locations throughout North America.

I worked hard, and continued to move into new higher level positions. I felt I was respected and had the resources to continue my development within the company. Many things have changed as we’ve grown, but quality and teamwork are still incredibly important. No matter what the project is, we never lack for people working together to get it done. Personally, I never hesitate to collaborate with anybody, even if it’s on a project outside my area of expertise.

My advice to employees joining DENSO is this: If you work hard, the possibilities are endless. Be a team player, good communicator and follow the DENSO Spirit!”

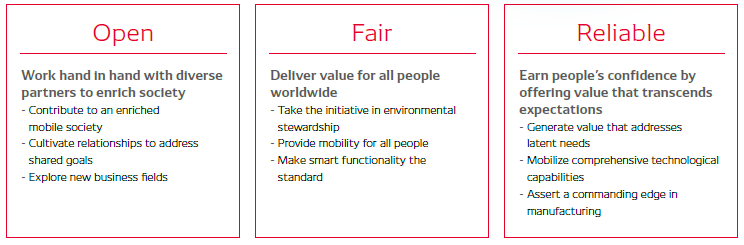

DENSO Sponsors SAE WCX Digital Summit

We are pleased to share that DENSO is sponsoring SAE International’s 2021 WCX Digital Summit, taking place April 13-15. The sponsorship helps DENSO connect with industry leaders, while advancing the conversation of how the automotive world can create safer and more sustainable mobility through innovation and working together.

DENSO’s presence at this year’s show will include:

- A keynote presentation titled, “Edge Computing in ITS (Intelligent Transportation Systems),” on Wednesday, April 14, 11-11:30 a.m. ET. Roger Berg, vice president of North America Research and Development at DENSO, will discuss connectivity’s increasing role in mobility ecosystems.

- A panel called, “Leadership Summit: Evolution of the Vehicle Architecture,” on Tuesday, April 13, 4:15-5:30 p.m. ET. Mike Murzyn, vice president of Engineering in DENSO’s mobility products group, will discuss among others the growing need for collaboration in vehicle development as they become more complex.

To register, go here: https://bit.ly/3e19GpU

“I look forward to not only sharing how edge computing contributes to intelligent transportation systems, but also learning from other presenters about how they’re tackling our industry’s biggest issues,” said Berg. “SAE WCX is always a great give and take, underscoring the need for all of us to leverage each other’s strengths to make mobility cleaner, safer and more efficient.”

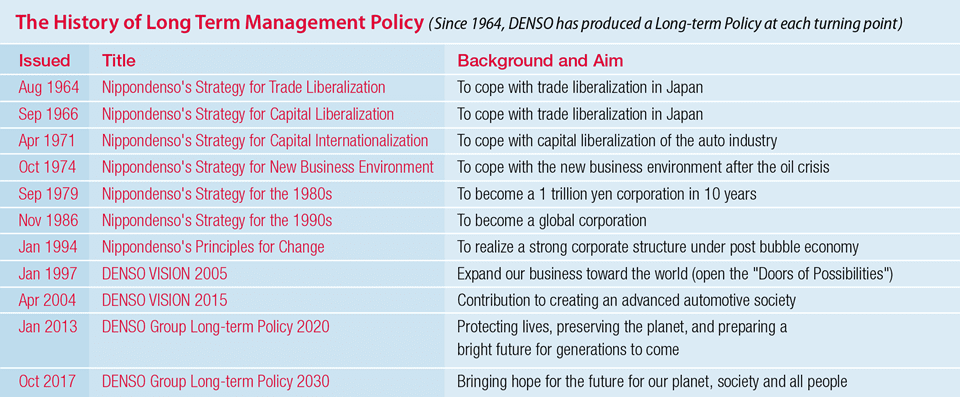

This year’s event arrives as DENSO is recommitting to its two great causes: “Green” – acting environmentally friendly – and “Peace of Mind” – creating seamless and safe mobility for all. This is part of Reborn 21, the company’s internal plan to build a leaner and more robust corporate structure and respond flexibly to new market needs. It will also propel DENSO toward its Long-term Policy 2030, focused on enriching mobility and the well-being of society.

Beyond 2030, DENSO aims to become carbon neutral by 2035. To accomplish this, the company is focusing on three areas: manufacturing, mobility products and energy use. DENSO has already begun the effort, recently launching its first CO2 plant at its Anjo Electrification Center in Japan to capture and recycle carbon and help power the facility.

New Lexus and Toyota Cars Feature Our ADAS Products

Today, our global headquarters announced we have developed products for Advanced Drive, an advanced driver assistance technology featured on the new Lexus LS and the new Toyota Mirai. Both vehicles, and our new technology, will be on the road this month!

Advanced driver assistance technologies are essential to helping drivers safely operate vehicles. The products that we have developed will support drivers on expressways and other motor-vehicle-only roadways, allowing the Advanced Drive system to detect hazardous situations, make decisions and assist driving under the driver’s supervision.

With these new products, we will contribute to advanced driver assistance technology that gives peace of mind to occupants and improves the safety of vehicles. They are part of our broader commitment to developing mobility technologies that help create safe and flexible mobility for drivers and pedestrians alike.

To learn more about the advanced driver assistance technologies we’re contributing, follow this link: https://bit.ly/3s4vmGS

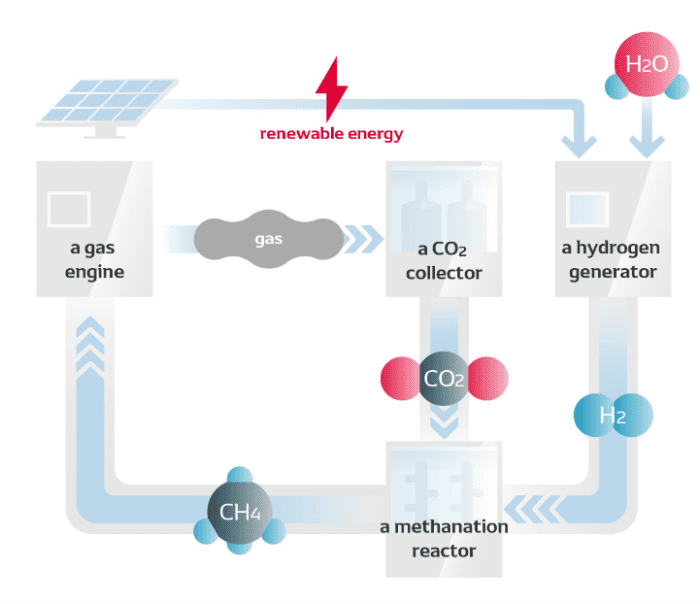

New CO2 Circulation Plant Supports Our Carbon Neutrality Goal

Today, our global headquarters announced that we have begun testing a CO2 circulation plant at our Anjo Plant’s Electrification Innovation Center. The new plant will capture CO2 generated by the plant and recycle it as an energy source for the facility, a capability that supports our efforts to eliminate CO2 emissions from our facilities.

More broadly, this CO2 circulation technology can also be applied to not only our production facilities, but to manufacturing sites around the world, which will help with efforts to achieve carbon neutrality.

The plant represents the latest initiative in our broader commitment to sustainability, and our Reborn 21 focus areas of “Green” and “Peace of Mind.” With this, we continue to accelerate our efforts to achieve net-zero CO2 emissions, or carbon neutrality, by 2035.

For more details on the new plant, and our commitment to sustainability, follow this link: https://www.denso.com/global/en/news/newsroom/2021/20210407-g01/

DENSO Aims to Hire Almost 100 Interns, Co-Ops at NSBE Convention

Today we announced DENSO is sponsoring and attending the National Society of Black Engineers’ (NSBE) 47th Annual Convention, held virtually this year April 5-9. Our support is part of the company’s continued focus on improving diversity and inclusion (D&I) not just within our own walls, but across the automotive industry.

“Mobility is constantly evolving,” said Denise Carlson, vice president of DENSO’s North American Production Innovation Center and the company’s executive lead for D&I. “In order to meet its changing demands, we are building teams with people who have dynamic backgrounds and perspectives, which helps us innovate more quickly and create more impactful solutions. It’s why we’re at NSBE, and it’s crucial to our future success.”

During the event, we look to hire nearly 100 co-ops and interns for summer 2021, fall 2021 and spring 2022. Roles will be available at various DENSO locations, including our North American headquarters in Southfield, Michigan; our thermal manufacturing facility in Battle Creek, Michigan; and our manufacturing facilities in Osceola, Arkansas, and in Athens and Maryville, Tennessee. Know someone who might be interested? Send them here: https://bit.ly/3fcCHRI.

We also intend to hire participants for our IGNITE Program, a two-year rotational assignment that offers recent college graduates unique career development opportunities, virtually and in person, at different DENSO sites. These roles will be based in Southfield, Michigan; Plano, Texas; and Maryville, Tennessee. Direct those who might be a fit to this link: https://bit.ly/31B7bFi.

For more about our presence at this year’s event and why it’s important to creating more inclusive work environments, go here: https://bit.ly/3mqhO76

Associate Spotlight: Beth Rollins, Excelling in Manufacturing Planning & Women’s Empowerment

All roads lead home. But for Beth Rollins, manager of Excellent Factory (EF) Planning at DENSO in Maryville, Tennessee, all roads lead back to DENSO. After leaving the company in 2012, she returned in 2018.

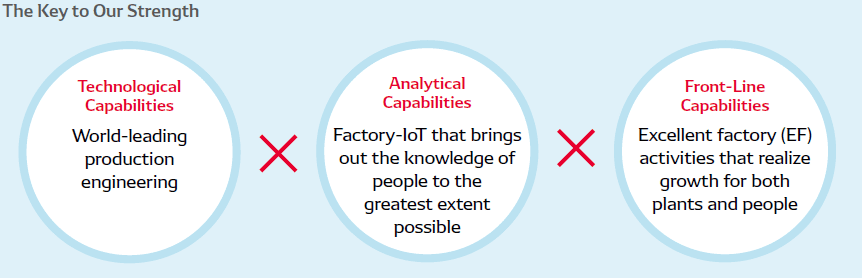

And she’s making quite an impact. She leads a team responsible for coordinating EF activities across the campus and serves as the engineering function in logistics and warehouse areas. Beth’s dedication to her job and team resulted in a peer nominating her for The Manufacturing Institute’s 2020 STEP Ahead Awards, which annually recognize women in science, technology, engineering and production careers who exemplify leadership within their companies

As if her “day job” doesn’t keep her busy enough, Beth is on the Maryville facility’s diversity and inclusion (D&I) steering team, helps lead their D&I task force and is co-chair of the site’s first Business Resource Group (BRG), Ladies Excelling at DENSO (LE@D).

Before DENSO launched its BRG policy in 2020, LE@D existed, but in a different capacity. Known as E3L (Engineering Ladies Lunch and Learn), the group, led by Beth and her colleague April Banner, brought female engineers from across campus together monthly for networking and training. Beth and April quickly realized the material being covered and discussed was of interest to an audience beyond engineers, so the group expanded to include associates from both technical and non-technical areas.

As part of DENSO’s observance of Women’s History Month and International Women’s Day, LE@D organized a panel discussion with three females at different stages of their careers and representing a variety of industries. This allowed attendees to hear diverse viewpoints and walk away with insights for their own careers and life. According to Beth, a co-host of the panel, her key takeaway was, “the importance of challenging ourselves, challenging others, challenging the status quo and challenging the systems.”

“I am proud of the BRG that April and I started,” said Beth. “Our forum has provided the opportunity for women from across campus who normally wouldn’t cross paths in their daily jobs to meet one another. It’s a form of collaboration and one way we align with and uphold that value of the DENSO Spirit.”

Beth is also fulfilled by her manufacturing career and sees women as a vital asset to the future of the industry, helping to fill the skill gap that exists and continues to grow. “Women bring a unique perspective that increases creativity and innovation,” she explains.

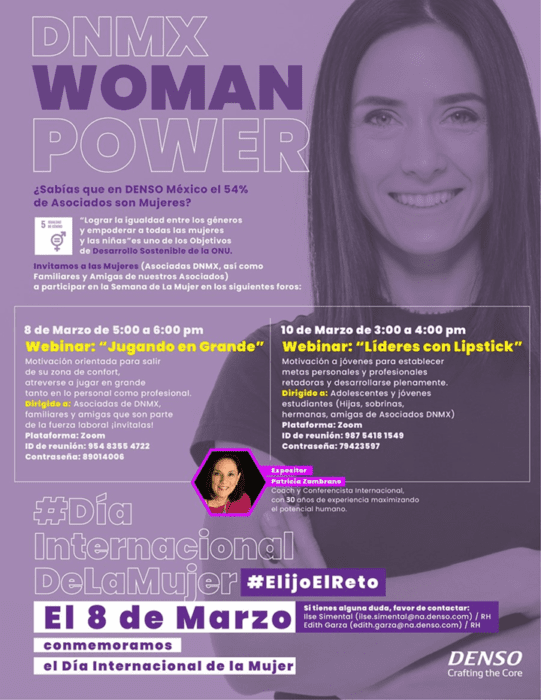

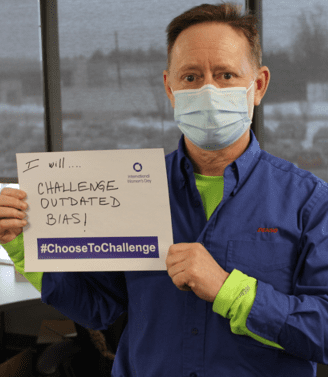

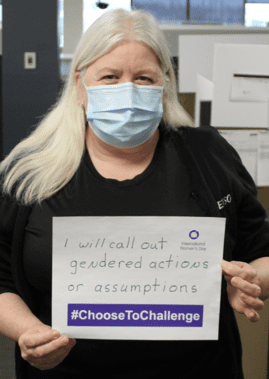

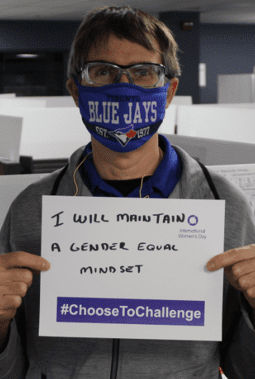

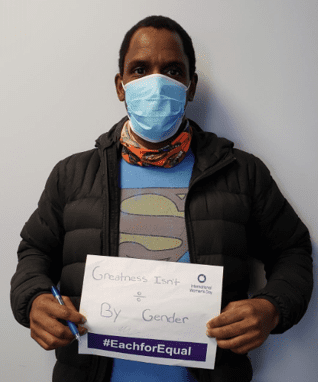

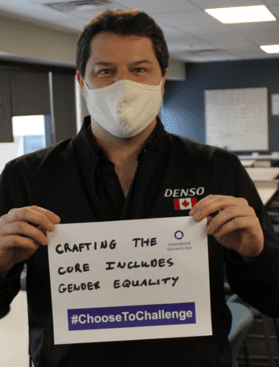

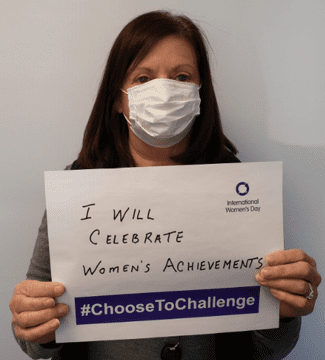

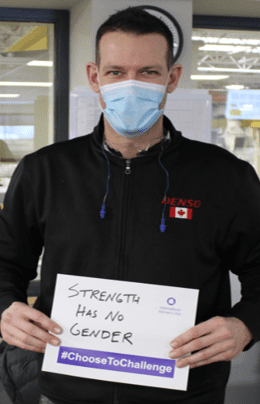

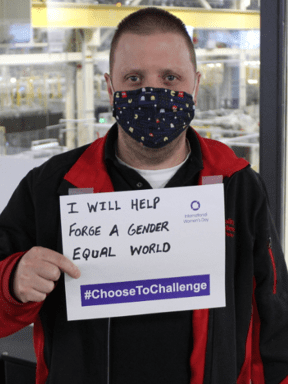

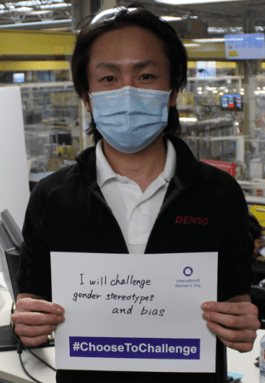

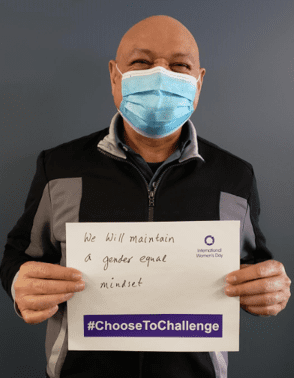

Activities for Women’s History Month & International Women’s Day

If you are looking for ways to recognize and support gender equality through activities surrounding Women’s History Month (WHM) or International Women’s Day (IWD) on March 8, we’ve got information for you!

#ChooseToChallenge

Participation is easy:

- Review the DENSO-selected challenge declarations below and choose one that speaks to you.

- Look for promotions at your site to get a card/sign, download from the IWD site, or make your own.

- Take a selfie with your declaration.

- Post your selfie to your personal social media account, using the hashtags #ChooseToChallenge and #IWD2021.

- Email your selfie to Communications@na.denso.com, so we can share some of your selfies on our TV system.

Need some inspiration? Click here to check out selfies from associates and leaders at DENSO Manufacturing Canada!

Other Activities

In addition to the #ChooseToChallenge activity, sites have various activities planned for IWD and throughout the month. Here are some of the events; be sure to look for information on WHM and IWD activities at your local site and on the DENSO Mobile App calendar.

Tennessee

-

- Holding a panel discussion with local community leaders on March 8, 12-1pm ET. Contact Beth Rollins or April Banner for registration details.

- Hosting a donation drive for kitchen, office and home items to benefit local women’s charities.

Canada

-

-

- Encouraging associates to wear work-appropriate purple clothing to support IWD.

- Conducing a raffle to benefit Girl Guides Canada; the company will match all funds raised.

- Holding an IWD quiz with prizes for perfect scores and the teams with the highest participation.

-

Michigan

-

- Encouraging attendance at the Manufacturing Institute’s “Virtual STEP Forward” event on March 8, 1-2pm ET. To register and join the event, click here.

- Hosting a DIAM Women’s Panel on March 22, 11:30am-12:30pm ET. To receive information, contact Lauren Lindell.

- Holding a North America BRG Happy Hour on March 29, 4-5pm ET. To receive information, contact Lauren Lindell.

Mexico

-

- Hosting webinars (presented in Spanish) on March 8 and 10. For more information, check out this flier (in Spanish) or contact Ilse Simental or Edith Garza.

- March 8, 5-6pm CT

“Jugano en Grande” (Playing Big)

Purpose: to motive and empower female workers to set big and challenging goals for personal and professional life. - March 10, 3-4pm CT

“Lideres con Lipstick” (Leaders with Lipstick)

Purpose: to motivate and empower young female students to set big dreams and develop their skills.

- March 8, 5-6pm CT

- Hosting webinars (presented in Spanish) on March 8 and 10. For more information, check out this flier (in Spanish) or contact Ilse Simental or Edith Garza.

We look forward to seeing your selfies!

DMCN Associates #ChoosetoChallenge for International Women’s Day

Associates at DENSO Manufacturing Canada #ChoosetoChallenge as part of International Women’s Day, calling out gender bias and inequality and celebrating women’s achievements.

Associate Spotlight: David Huguley – Quality Engineer, Minister, Change Agent

We all need more hours in the day. But you know who really needs them? David Huguley, a manager of Quality Engineering at DENSO’s North American headquarters in Southfield, Michigan, who on April 3 will celebrate his 26th year at the company.

When he’s not leading Quality Systems Improvement efforts – a demanding task in its own right – you can find him doing a range of things to serve those around him:

- As a certified minister, marrying couples, conducting eulogy services, counseling couples and previously incarcerated people, and contributing to weekly DENSO bible study meetings;

- As a coach, leading youth basketball, baseball and football teams;

- As a family man, loving his wife of 32 years, raising two biological and five fostered sons, and organizing their annual family reunion, which connects nearly 100 family members from across North America; and

- As an associate, mentoring junior associates and cofounding one of DENSO’s newest business resource groups, the DENSO African Ancestry Network (DAAN).

How does he keep up with it all?

“Through passion,” said Huguley. “The passion I have for ministry work is not work. And I’m very organized – it helps me do all the things I need to.”

Passion and organization go far, especially when it comes to quality, a foundational value at DENSO. Since 2018, Huguley has overseen Quality Systems Improvement and Quality Management Systems initiatives at DENSO sites in the southeastern U.S., including Maryville and Athens, Tennessee; and Statesville and Greenville, North Carolina. In this role, he leads a team focused on standardizing and optimizing the locations’ quality processes, an effort that not only strengthens DENSO’s products, but also increases operational efficiency, cuts costs and speeds production.

These are proud achievements of his, but Huguley says he gets more satisfaction from mentoring interns and IGNITE Program members, and helping them grow their careers.

“In my time at DENSO, I have played a direct part in hiring 10-15 full-time associates,” explained Huguley. “The longest tenured engineer I mentored just celebrated 14 years at DENSO and is a very high performer. It’s so gratifying to see all of them develop personally and professionally.”

Huguley’s penchant for service leadership and inclusivity inspired him to do more, so he helped cofound DAAN, a business resource group dedicated to supporting and expanding opportunities for African Americans at DENSO.

“I want to be a change agent within DENSO,” said Huguley. “And while there are many avenues to do that, with DAAN, our vision is to reach new heights in diversity, engagement, hiring and helping associates succeed. DENSO already does lots of community work, but we want to push that even further too.”

The introduction of business resource groups is part of DENSO’s broader transformation guided by Reborn 21. The internal initiative – which leverages DENSO principles such as DENSO Spirit, “Green,” meaning environmentally friendly, and “Peace of Mind,” meaning safer world for all – intends to make the company more competitive as mobility evolves.

That transformation extends to diversity and inclusion (D&I), an area key to fostering more welcoming and productive work environments at DENSO. And while DENSO is making progress, there’s still much to be done. Huguley will be instrumental in this, but it will take all DENSO associates to meet our D&I goals.

With it being Black History Month, Huguley closed with this reflection:

“Black History Month to me is an opportunity to reflect on our heritage and how our ancestors have paved the way for so many of us as people of color,” said Huguley. “It’s truly a time to celebrate the accomplishments and contributions of African Americans and to reflect on the many struggles, barriers and injustices that so many people of color have endured over the years. Yet they still survived and strived. Everyone should educate themselves on the significant influence of African Americans in our U.S history.”

To learn more about business resource groups or to access resources to establish one, login to DENSO Mobile, click on Folders / Diversity & Inclusion. For questions or assistance in creating a BRG, contact your HR Team Member Solutions representative.

Creating a D&I Culture – One Line at a Time

A little over three years ago the HR legal team at DENSO Manufacturing Mexico wanted to establish a production line tailored to associates with a disability. So, with the help of DENSO HSE and a Mexican government organization that focuses on the needs of people with disabilities, the site began looking at studies and conducting trials to identify the specific disability that could safely and effectively be implemented in a production environment.

The group determined that a molding line for those with hearing impairments would work. Today, 14 associates with hearing disabilities work on the line, alongside associates with no hearing impairments. But it didn’t happen overnight. The HR legal team, along with plant leadership wanted to ensure that everyone was prepared and informed, so there was awareness training on non-discrimination and harassment for team leaders and associates. And to assist with communication outside of writing, team leaders and associates that would be working directly with the hearing-impaired associates learned basic sign language.

But it wasn’t just the people that adapted – some plant processes and systems had to be changed. For example, all plant safety and security measures are now visual – alarms/alerts are not auditory – and training on what each light means and what they need to do when they are activated was provided.

Admittedly there were some bumps along the way – getting everyone on board for new processes and mindsets took some time, and awareness training had to be expanded to people working in areas within the facility, such as the cantina, to ensure everyone was comfortable interacting with the hearing-impaired associates.

The line has successfully operated for more than a year and there are plans to not only expand the line to 20 associates, but establish lines, possibly for those with other disabilities, in other plants on the campus.

Congrats to the local DENSO HR legal team in Mexico for making this happen. It’s a great example of how everyone can work together to create a successful, thriving D&I culture at DENSO.

All photos were taken before the COVID-19 pandemic. During COVID-19, DENSO established and continues to maintain safety precautions at all of its locations, including the wearing of face coverings, social distancing and screenings.

DENSO New Hire Spotlight: Jami Carpenter

Welcome to the team, Jami Carpenter! Jami recently joined DENSO’s North American team as a Production Control Specialist and is ready to put her strong work ethic into practice.

“I’m driven to want to do a good job,” said Jami. “I always want to learn and expand my capabilities into new areas, and I feel that DENSO creates great opportunities for me to do so.”

Jami became a DENSO associate just as businesses across North America started adapting to combat the effects of COVID-19. While this created new challenges, Jami said that the most important thing to her was that she felt safe working at her facility.

“I think DENSO is doing a great job at following all of the proper guidelines under the current circumstances. The temperature checks and mask requirements make me feel like it’s safe to walk into work every day.”

Even though it took some extra time to get onboarded remotely, Jami saw DENSO working hard to make her feel connected throughout the experience. Programs like Microsoft Teams and Web Ex have made her team meetings seamless. The DENSO Mobile app has also helped her stay informed on what is happening within her own facility, as well as within the entire company.

DENSO New Hire Spotlight: Arthur Cardente

We’re excited to welcome Arthur Cardente to the DENSO team! Arthur is our new Regional Sales Manager for DENSO NA’s Northeast region.

Joining a new company in the midst of COVID-19 can be difficult. But despite the challenges, Arthur shared that one of the benefits of joining a team like DENSO’s was his colleagues’ willingness to help him adjust to his new role.

“Everyone has been truly helpful and more than willing to do whatever is needed for me to gain a better understanding of the day-to-day procedures,” said Arthur.

His remote work environment hasn’t discouraged team bonding. In fact, Arthur said he’s thankful for having a team that not only prioritizes making everyone feel welcome but also cares deeply for the health and wellbeing of himself and his family. DENSO made sure that all facets of its safety protocols were being implemented and enforced, and constantly checked in on Arthur’s safety as well as his family’s health.

Arthur shared that he’s excited to work for a world leader in quality, service and manufacturing.

“I hope that in the years to come, I won’t only learn more about this fine organization, but that I can also lend my knowledge, contacts and experiences towards making DENSO a greater company as we move into the future.”

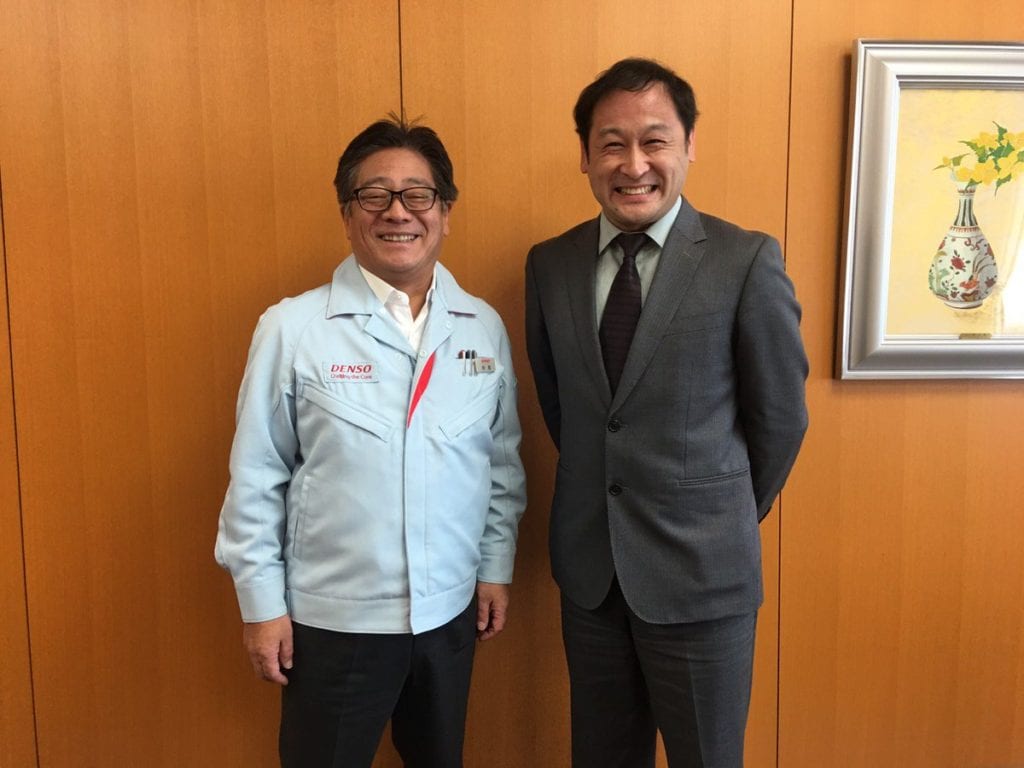

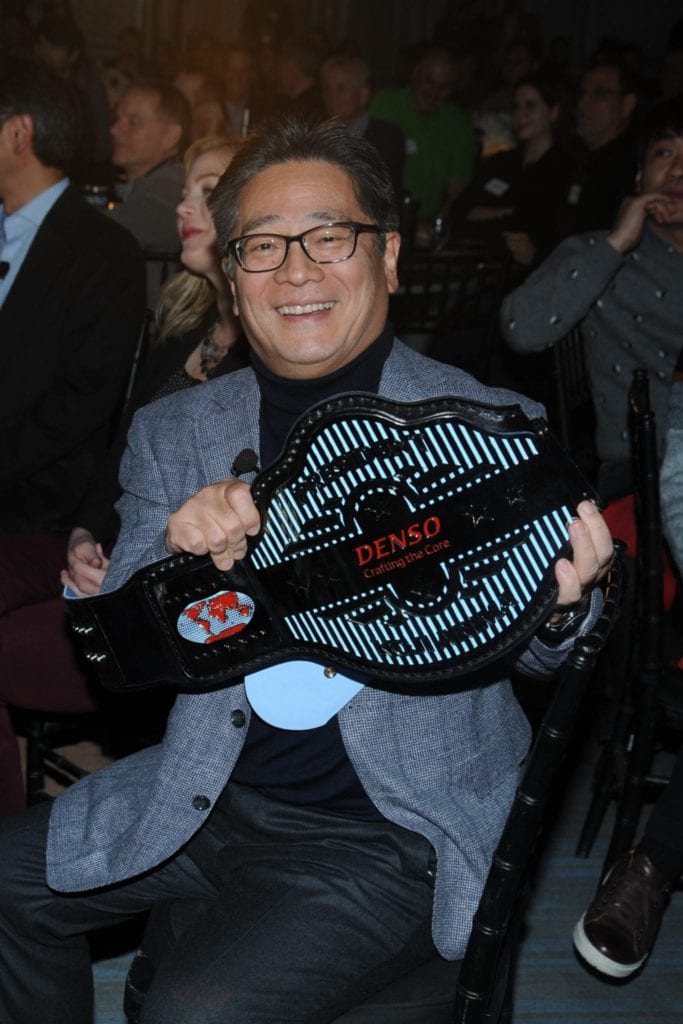

Introducing our new North America CEO Seiji “Scott” Maeda

Get to know our new CEO of DENSO in North America and President of DENSO International America – Seiji “Scott” Maeda!

Associate Spotlight on Tracey Wall: Transferring from Sales to HR

Tracey Wall

Human Resources Planning Lead

Transferred from Toyota Sales Department to North America Human Resources

It’s been just over one year since I made my internal transfer – it’s been a good and incredibly valuable experience for me. After spending 23 years in Sales, I was ready for a change; I wanted to find a new way to add value to DENSO. Since I had requested a change to another function, it took over a year to find something, but Sales and Corporate Function management were very supportive.

Though I was looking for a change, there was some fear in such a drastic transition. I was leaving a position where I was the go-to person for the customer. I knew the job and my value/contributions to the company. What exactly will I be doing in HR? What value would I be bringing to the new position and company now? How would I show my value/contributions quickly? There were a lot of questions – I wasn’t quite sure what I was signing up for.

But that’s when I remembered that I know DENSO and the values we all hold. Despite different divisions, plants or roles, we all have common, fundamental DENSO values and way of working. Yes, I had a lot of sales knowledge and contacts within DENSO throughout my career, but I realized this was not exclusive to the sales role – it would (and has been) helpful in my new planning role.

The HR team was great – they were very welcoming and showed me the ropes. But I’m a department of one, so I had to proactively insert myself into meetings and teams across NA. In my role I get exposure to many aspects of our business – I get to hear and understand the bigger picture and how executives discuss, consider and make decisions on various issues. I’ve appreciated this new insight into our company, it has given me new understanding about why and how things are done and ultimately, reinforced my respect for and dedication to DENSO.

My transfer has been an invaluable experience for me. I definitely miss the people in Toyota Sales and certain aspects of the job, but I’m enjoying my new department, have broadened my skill set and am contributing to the company in a new way. And as it turns out, my timing was great – joining HR right before a global pandemic, now THAT has been an incredible experience!

My Advice to You:

For those thinking of making a change, I have a couple pieces of advice:

- Don’t let fear or hesitation stop you – you will overcome it. I loved my sales department and team, but knew I was going into a department with good people. No matter where you go, there’s going to be people to support you and that you’ll enjoy working with.

- Don’t underestimate yourself. Just because you are in one function and will have to learn things in a new job, the DENSO fundamentals are the same.

- Do it for the right reasons. Don’t look to make a major transition just because you’re not happy with one aspect of your job. Remember, the grass is not always greener – it is a different texture and shade of green.

Search for Open Internal Positions

- Go to densocareers.com

- Click “DENSO Employee”

- Login with your DSC-ID and Oracle Fusion password

- Search for open positions and apply!

The online internal application system only shows non-exempt and exempt office positions at this time. For all other positions, please view local job boards and follow the local application process.

Spotlight on Matthew Johnson: Transferring from Thermal to R&D Engineering

Matthew Johnson

R&D Engineer

Transferred from a design engineer role in Thermal Engineering to R&D engineer at Collective Works (previously New Product Innovation)

My internal transfer experience wasn’t anything radical – I went from one engineering job to another. But my fear in pursuing the transfer is something I think others might experience, so I want to address it.

I felt like I was under a lot of pressure to win the Collective Works team over and transfer successfully because if I failed to get the job, it would then be known I was looking to make a move during a time my department was reducing head count. Would it look bad that I was looking for a new position? Would I be jeopardizing my job or chance for advancement?

Retrospectively, there was nothing to worry about or fear. I know others who applied for but didn’t get transfers and they have not experienced any negative backlash. I understand now that the company is supportive of transfers – it helps them and you as an individual. In fact, when I accepted my new job, my new and current managers met and discussed a transition plan that worked for everyone. And when I got to my new job, my team trained me on equipment and software I’d be using and were always available to answer questions – they were very supportive and patient.

I’m very happy I made the move. Moving to an R&D role in NAREC (North America Research and Engineering Center) gives me the opportunity to explore new spaces, solve new problems and develop new products and technologies. This is what I was looking for with a move. I went from maintaining and creating drawings for car parts to researching market trends, identifying the most valuable problems to solve and fabricating concept solutions to address problems in new spaces where DENSO can win!

So, if you are worried about the optics of applying for a transfer, don’t. Just go for it.

Search for Open Internal Positions

- Go to densocareers.com

- Click “DENSO Employee”

- Login with your DSC-ID and Oracle Fusion password

- Search for open positions and apply!

The online internal application system only shows non-exempt and exempt office positions at this time. For all other positions, please view local job boards and follow the local application process.

DENSO Tenured Associate Spotlight: Karen Croly

When you know, you know. And when it comes to finding “the one,” you don’t let go. Just ask our many tenured associates. Through name changes, shifts in company direction and new, innovative technologies that advance mobility, our tenured associates have shown their DENSO Spirit every step of the way.

Karen Croly, who works within the purchasing department at DENSO’s Southfield facility, has been part of the DENSO family for more than four decades (wow!). She’s one of our longest-tenured associates to date. And while we could tell you all about Karen’s time at DENSO — how she’s grown her career, how her colleagues have become family (literally) — we thought who better to tell you about her experience than Karen herself. Here’s what she had to say:

“It was nearly 41 years ago (October 1979) when I went to Nippondenso (DENSO’s name back then!) for my first interview. I decided to go with DENSO because it was a smaller company and I wanted to grow with them and learn from other associates. DENSO was always a great place to be taught everything, from work product, processes and making friends for life.

My first duties were secretary to the vice president and then for several Japanese men who worked for other companies (ASMO, Tokai-Rika, and Toyota Automatic Loom Works) but were housed at DENSO so they, too, could develop customer relations in the U.S. under the guidance of our first president, Akira Kataoka. I can’t say enough good things about Kataoka-san. He knew how to communicate and engage with people in every level of the job as well as his success with our customers. He was always approachable and willing to share to help develop DENSO and its associates.

I remember that one person in the office each week had to make coffee for everyone in the morning. When the afternoon rolled around, it was Akira Kataoka, our president, who made iced coffee for everyone who wanted it. It was just one example of how he made us more of a family than a workplace.

From being a secretary to working with sales and engineering personnel through the years, I ended up in Purchasing, where we built our processes and plants in several locations around the country. By this time DENSO was a very large company, but the family atmosphere continued to thrive for many of us.

During my time at DENSO, I married my boyfriend, John, and we had two beautiful daughters, Jillian and Stephanie, and now I have a wonderful son-in-law, Nick. They have all been a big part of my work life and they, too, have developed friendships through my work. I even introduced a fellow co-worker to one of my nieces, and they have been married for many years and have two great boys.

Our newer associates should remember a couple things. It is beneficial to be taught things that you can use at another time in your life. Keep an open mind and always enjoy your work. Learn to listen, but also be heard. Always make time for your family and friends, and keep a balance of your personal life and work. If you develop friends at work, then work is easier to handle. Show your personality to others and communicate with co-workers, as they, too, can become your friends. Your ideas are what make a better work environment and give success to our company.

My work career will soon be coming to a close as retirement approaches. This year of the pandemic is difficult, as I miss seeing and engaging with people. We all became one big happy family at our local spots. I will greatly miss the work and so very many of the people I have worked with over the years.

Thank you.”

[Video] President Arima’s 2021 New Year Kanji Message for Associates

Global President Arima shares his New Year message with associates in a single Kanji: “Katsu”. President Arima explains three meanings behind the word:

- Maximizing your energy

- Inspiring each other

- Liven up DENSO

This is his hope for DENSO and our associates in 2021!

Learn more in his video message, or click here to read an overview:

Wishing You a Happy New Year

As we start 2021, we want to thank you for all your hard work and support this last year. We’re inspired every day by the DENSO Spirit our teams show, and we look forward to continuing to build a brighter future, together.

Wishing you and yours a happy and healthy New Year!

Happy Holidays from Matt & Angie Smith

Happy Holidays from DENSO-sponsored NHRA Pro Stock Motorcyclists Matt & Angie Smith!

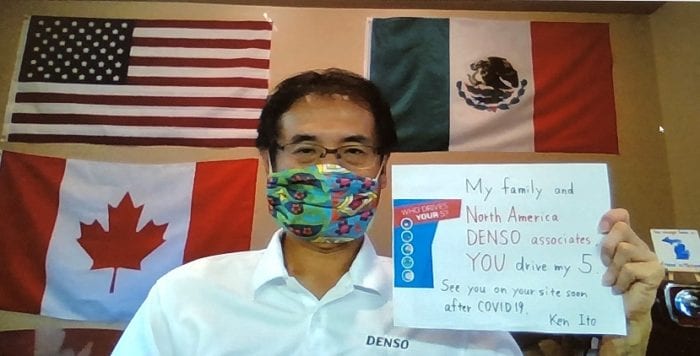

Have a Safe & Healthy Holiday – A Message from CEO Ken Ito

President & CEO Ken Ito wishes you a happy and healthy winter holiday!

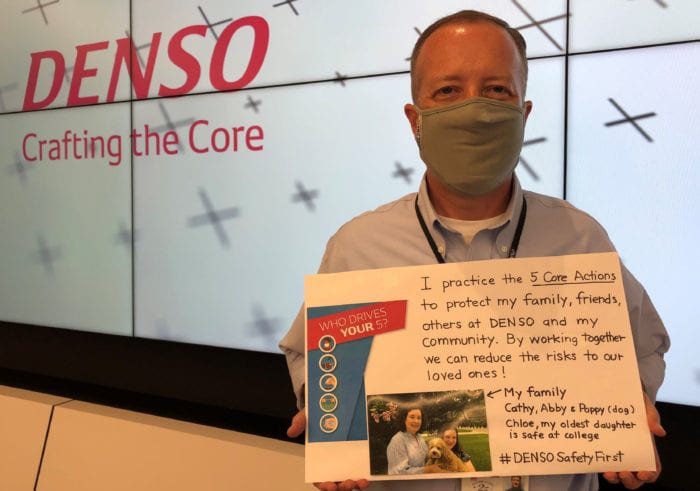

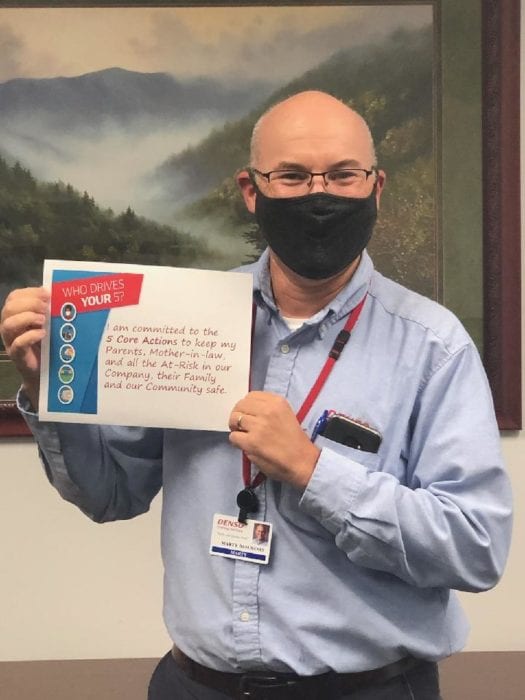

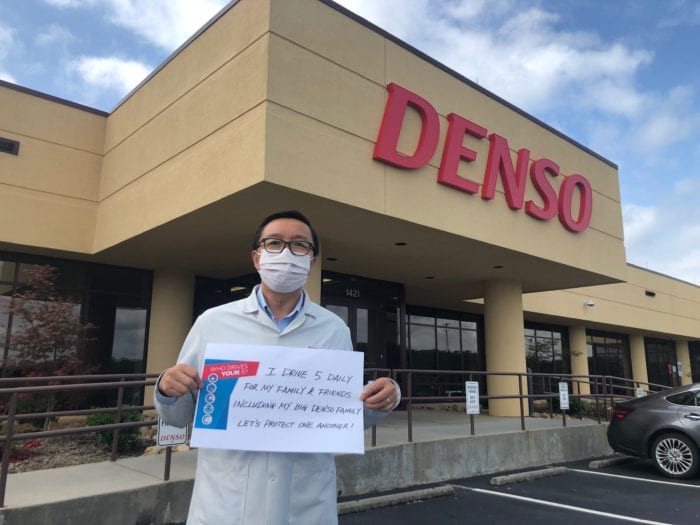

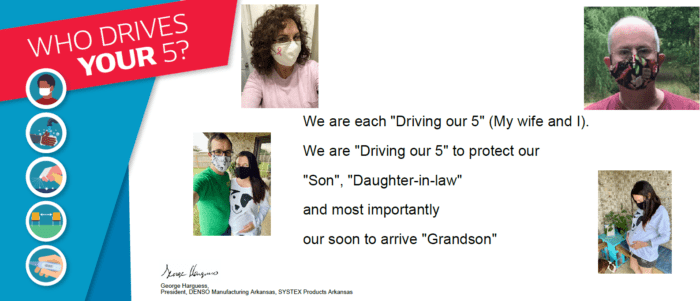

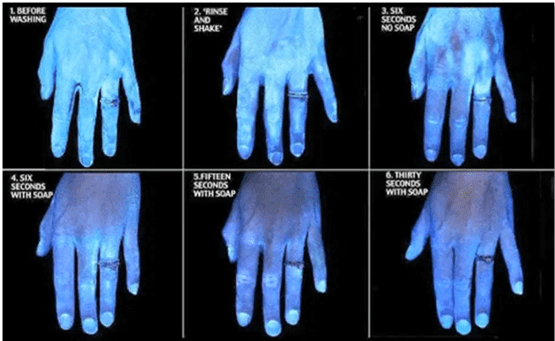

Protect you, family and friends this holiday season by following the 5 core safety actions:

- Monitor your health: Check your temperature regularly, stay home and quarantine when you’re feeling sick

- Social distance: Steer clear of crowds and confined spaces. Keep 6 feet distance to avoid close contact with others.

- Wear a face covering: When going out in public or seeing others outside your home, properly cover your nose and mouth with a face covering.

- Disinfect: Start and finish with a clean work area. In the home, frequently clean commonly used areas, surfaces, light switches, door handles, etc.

- Wash and sanitize hands frequently: Wash with soap and water for 20 seconds frequently throughout the day.

Happy Holidays!

DMTN Celebrates 30 Years

Our team in Maryville, Tenn. just celebrated a major milestone: its 30-year anniversary! Join us in applauding them for decades of quality service and important contributions to the Volunteer State.

We recognized the achievement at a socially-distanced and digital-ready ceremony, where DENSO and state leaders highlighted the location’s significant impacts on DENSO, Blount County and the auto industry. Thank you, Maryville team for your DENSO Spirit, and here’s to 30 more.

Farewell Message from Ken Ito, President & CEO of DENSO in NA

| Associates,

I am very grateful for the time I have spent as your North America CEO. I have had the opportunity to visit many of you over the past four years. You have welcomed me and taught me many things about the different cultures, diverse talents and perspectives across North America. I have many fond memories with you – North America Quality Circle Competitions, the New Year Ceremony, openings of DIAM satellite R&D locations, and more. And, we have been through many challenges together, especially this past year with the coronavirus pandemic. I am continuously inspired by your challenging spirit, great compassion, talents, and dedication. Not only have you been a strength for DENSO, but also for our communities. I know that with your strength, DENSO can succeed and create a better future for many. I will move to Japan soon, but I am not really so far away. I will continue to support North America, and other regions, as Chief Human Resources Officer. I look forward to working with many North America team members in the future. There are great opportunities for North America to play an active role, or to lead DENSO, globally in various areas. I am excited to see the great things we can accomplish together. Thank you everyone. I will move to global headquarters, but will visit North America after we beat coronavirus. I hope it will come soon. Until then, stay safe, and please keep in touch. Please click here to see my farewell video message to associates. Thank you, Ken Ito |

DENSO Spirit Spotlight: Ravi Vadapalli

Venkata Ravisankar Vadapalli (Ravi, for short), a technical lead for DENSO’s phone-as-a-key (PaaK) project, was laser focused on making the development process run effectively when the team of 15+ engineers were working remotely.

The PaaK project started in 2017 with the goal of replacing traditional car key fobs with a customer’s smartphone to start the vehicle. Pretty cool, right?

While the first PaaK technology produced by DENSO entered the market in 2020, DENSO has continued to enhance the software. This is what Ravi’s team, BES2 (Body Electronic Systems2) Ford PaaK Team, was working on when COVID-19 hit.

Because of the work from home situation, the team was forced to use a very old tool that’s difficult to work with and slows down efficiency. Ravi oversaw switching the team to a different configuration tool, Github, to ensure they were able to deliver products on-pace and better contribute to the overall project.

This turned out to be more helpful than expected for Original Equipment Manufacturers (OEM) customers who have dynamic change requests. Normally, timelines are very short and it can be difficult to manage (not to mention stressful for the team) if a process isn’t in place. Using Github helped streamline the process, improved response times and created happier associates.

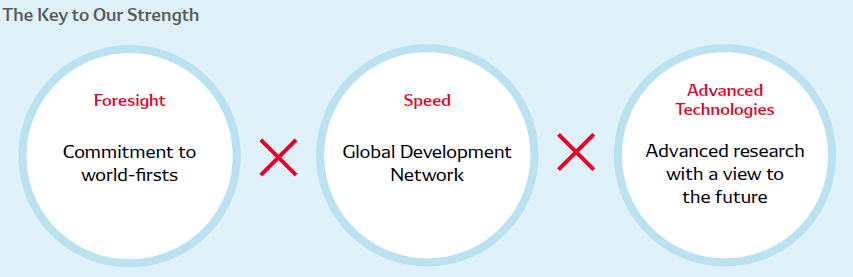

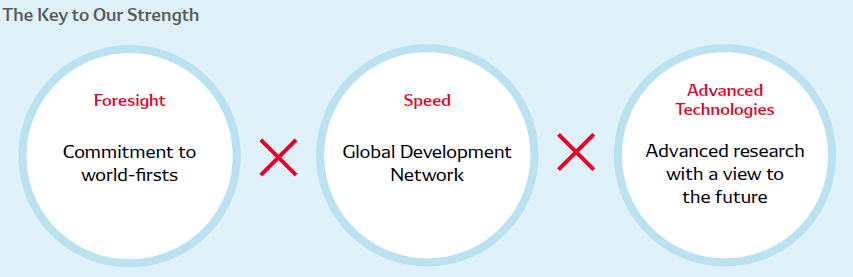

Thanks, Ravi and team, for not only getting creative and always putting the customer first, but living up to the DENSO Spirit that’s driven by foresight, credibility, and collaboration.

DENSO Recognizes 2021 STEP Ahead Nominees

In September, we called for associates to nominate exemplary female colleagues for the 2021 STEP Ahead Awards, a national honor given every year by the Manufacturing Institute to the best women leaders in manufacturing.

We asked and you delivered. From the c-suite to the production floor, here are the outstanding nominees you submitted to be considered for the awards:

- DIAM:

-

- Kara Grasso, VP of Strategic Operations

- Stacey Skerske, Senior Manager of Sales

- Amanda Gray, IT Support Staff Supervisor

- Denise Carlson, VP of NAPIC and Executive Lead for Diversity and Inclusion

- DMAT:

- Emilee Davis, Tie Project Leader

- Ashleigh Seay, Manager of Production Engineering

- Cheryl Reagan, Production Visual Inspector

- DMCN:

- Karen Whiteman, Engineer

- DMMI:

- Kim Shakinis, Senior Process Engineer

- Michelle Haviland, Advanced Process Engineer

- DMTN:

- Connie Sharpe, Section Leader, Quality Engineering

- Whitney Dye, Team Leader, Production

- Haley Penney, Senior Specialist, Quality Engineering

- Jananii Vaz, Senior Specialist, Production Engineering

- Rebecca Sargent, Team Leader, Production

- Monica Moore, Manager, Production

- Beth Rollins, Manager, Engineering

- April Banner, Section Leader, Production

- Mary Sutherland, Senior Specialist, Quality Engineering

- Tina Lakey, Manager, Quality Engineering

- Amanda Dango, Senior Specialist, Production Engineering

- DPAM:

- Ellen Yim, Purchasing Supervisor

Please join us in applauding all these DENSO leaders, who make invaluable contributions to DENSO every day and help us deliver on our principles of safety, quality and collaboration. We recognize the important impacts they make not only at DENSO, but in their communities and with friends and families as well.

What’s Next?

While we wished to submit all the nominees, the Manufacturing Institute is highly selective in its review process and only allows 10 submissions per company.

As a result, a DENSO review committee consisting of members from the Diversity & Inclusion Council, Corporate Communications, Human Resources and Government Affairs evaluated and submitted the nominations that best aligned to the awards’ criteria. Those criteria included examples of personal achievement, mentorship, leadership, and community and company contributions through specific results and data.

The Manufacturing Institute is expected to announce the winners on Jan. 8, 2021. If a DENSO associate wins, we will be sure to share!

Want to get involved next time?

Whether you were nominated this year or this is the first you are hearing of the award, know that next year you will have another chance to nominate yourself or another standout female leader from DENSO. We will share more details about how to nominate individuals – and how to make those nominations as strong as possible – closer to next year’s nomination window.

More About the STEP Ahead Awards

Produced by The Manufacturing Institute, an organization dedicated to growing and enhancing the industry’s skilled workforce, the STEP Ahead Awards recognize women in science, technology, engineering and production careers who exemplify leadership within their companies. The honor identifies top talent in manufacturing, and further encourages award winners to mentor and support the next generation of women to pursue manufacturing careers.

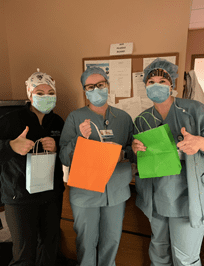

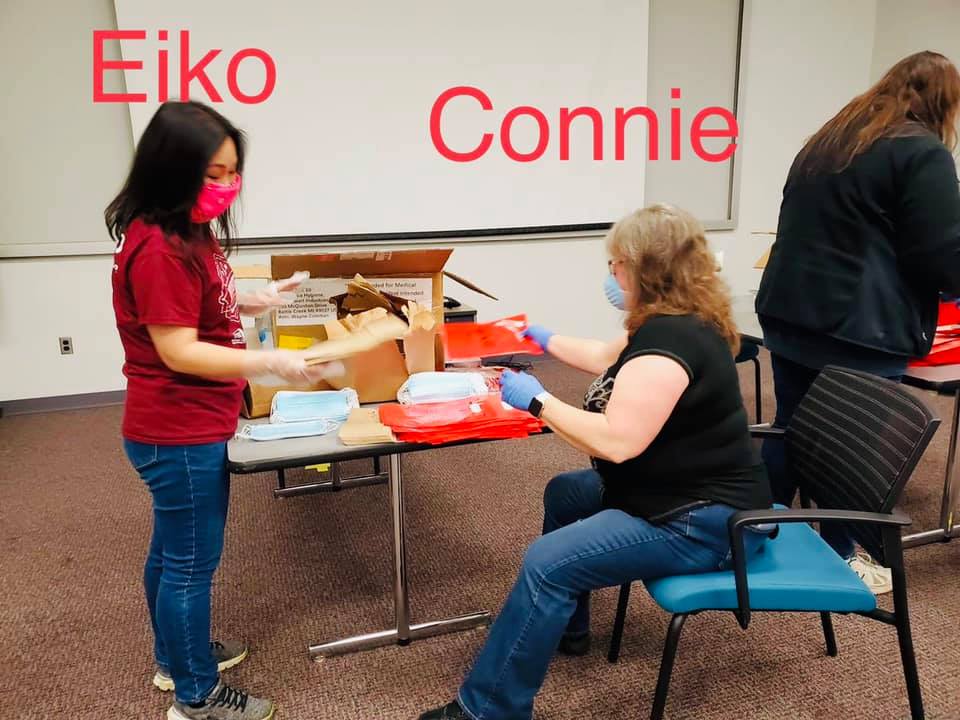

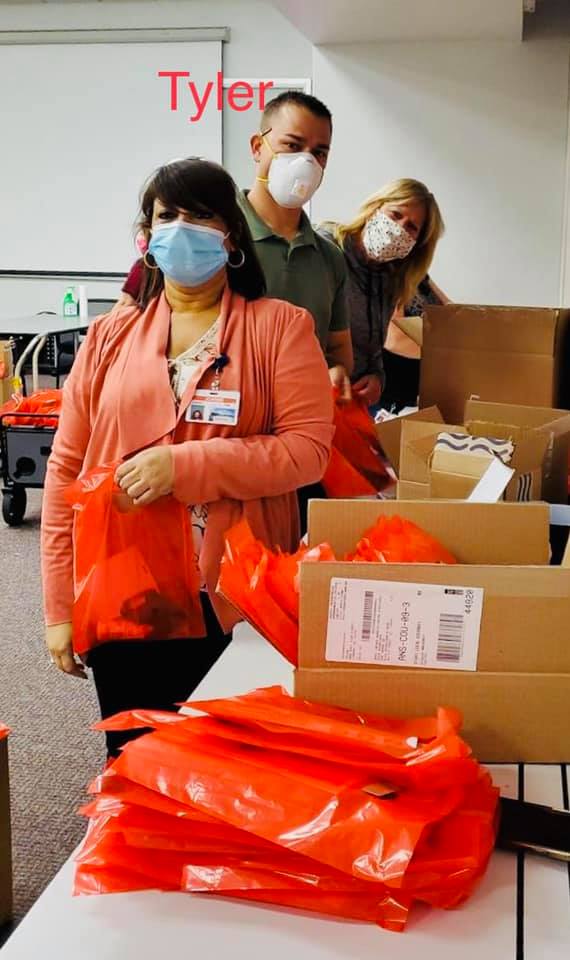

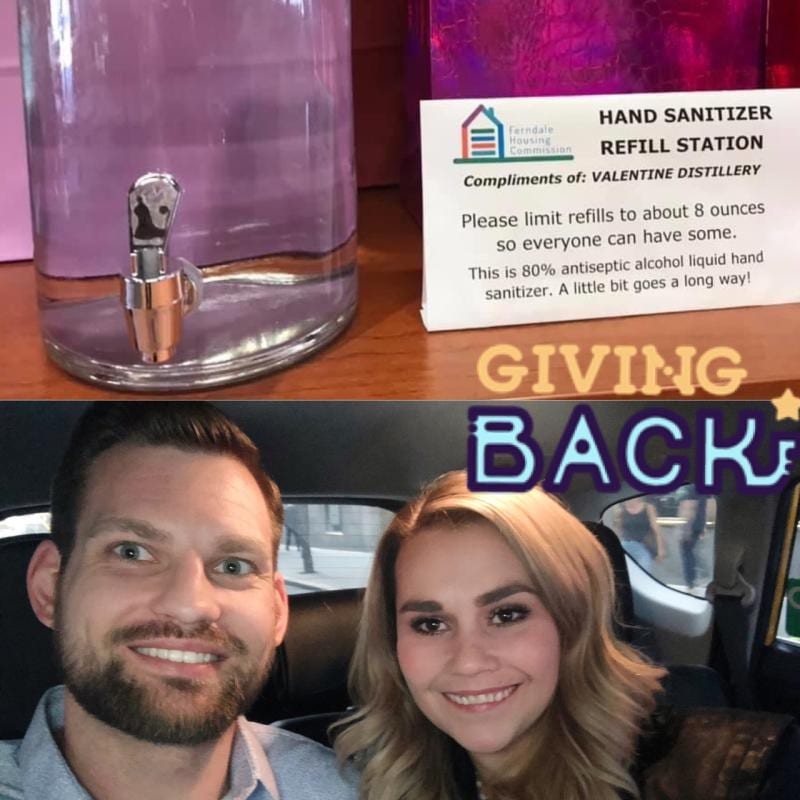

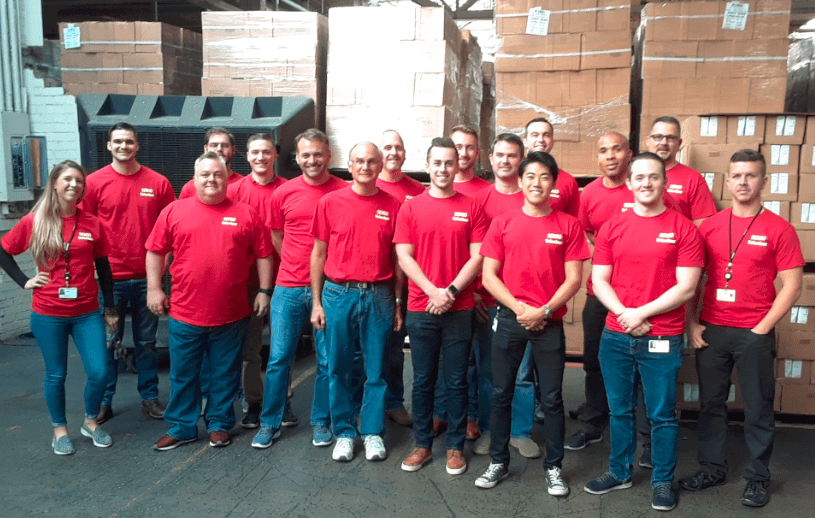

North America Gives Back

The year 2020 may have brought on a lot of changes but DENSO’s commitment to giving back did not change. Through adjustments, creativity and commitment, our associates across North America continued to give back to the communities we live and operate in.

Here are just some of the ways our associates and locations gave back this year:

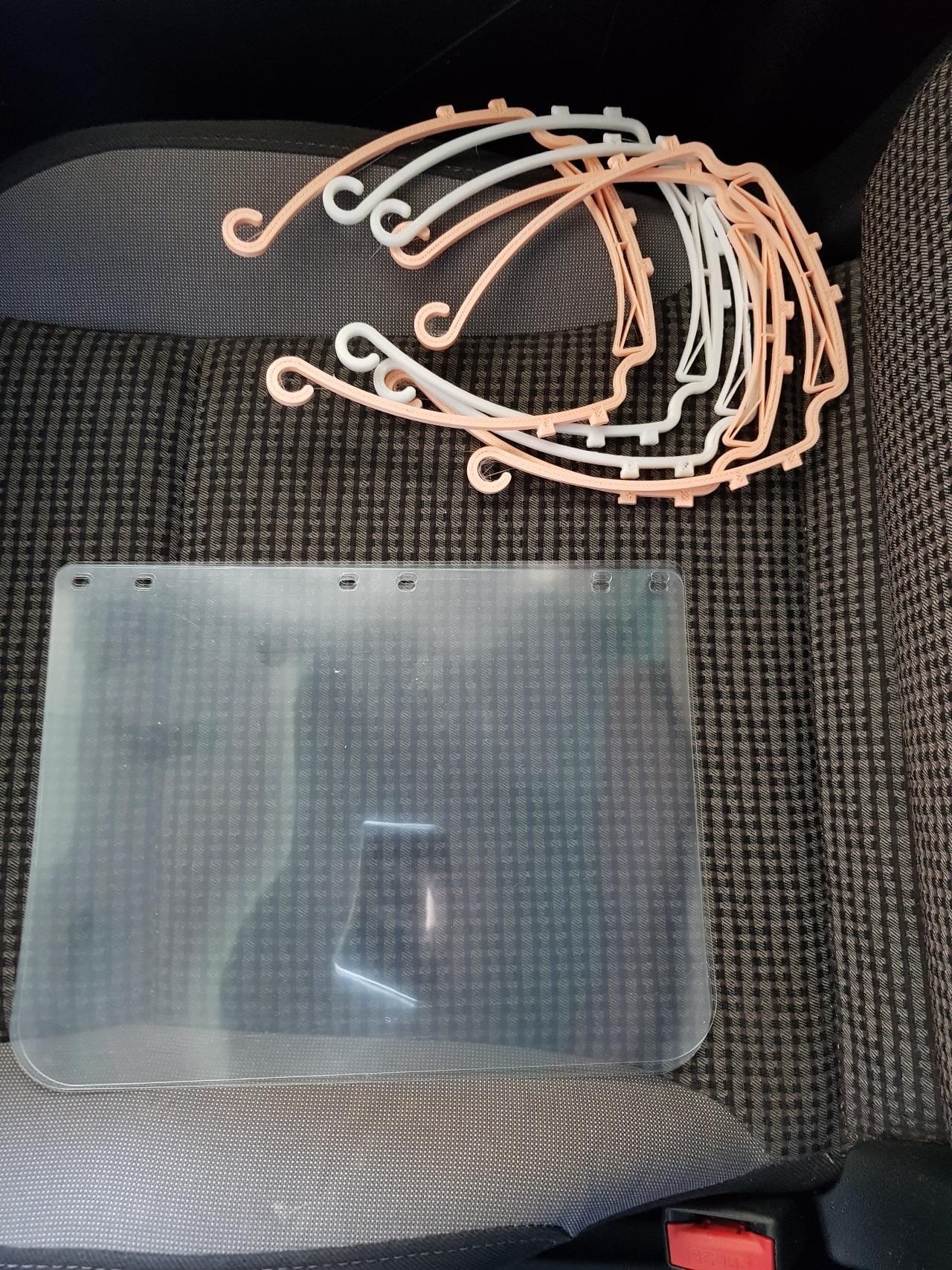

Face shield production and donations across NA

DIAM Food Packing Event

DPAM Turkey Donation

DMMI Environment Cleanup

DNMX Holiday Gifts

DMCN Coat Drive

DMTN Holiday Gift Drive

DMAT Reading to Students

Thank you and congratulations, DENSO Associates!

Our continued commitment during this difficult year were recognized with DMTN and DIAM being nominated for awards by their communities.

Tennessee Chamber of Commerce & Industry

- Outstanding Community Stewardship in 2020

- Excellence in Operations Healthy and Safety

United Way of Blount County

- Community MVP Award

- Ambassador of the Year

Southfield Chamber of Commerce

- Community Cares Nominee

- Chamber Member of the Year Nominee

We couldn’t do any of this without the efforts of our associates. Thank you for continuing to demonstrate the DENSO Spirit through your efforts to give back.

Ways to give year round!

For those still compelled to give back, some suggestions are:

- Buy Local — It’s no secret that local businesses have been hard hit by the pandemic. Thus, consider getting this year’s gifts from local purveyors or ordering holiday meals from local restaurants and markets.

- Give to Organizations Supporting Frontline Workers — While first responders have spent most of 2020 tending to the public, there are many organizations at national and local levels doing important work to support them, donating things like PPE, food and care.

- Support Local Food banks — Food insecurity is on the rise. And with more people looking to feed their families over the holidays, many food pantries are offering contactless ways to give so they can fulfill their missions safely.

- Donate Blood — Since the pandemic’s start, blood centers have reported an increasing need for blood donations. While COVID has rightfully grabbed much of the medical world’s focus, more blood means more people can get the care they need.

- Go Digital — Not all volunteer activities are in person. Online resources like VolunteerMatch help connect organizations with people looking to help in all sorts of ways, including online mentorship and other activities able to be done online.

Spotlight on Rob Wunsche: From Engineering to Sales and R&D

Rob Wunsche

Director of Engineering, Mobility Platform Services

Transferred from Engineering to Sales to R&D

Back in 2012, the DENSO Toyota sales team was looking for a technical person to join as a sales engineer because their current person was changing jobs. They approached me and admittedly, I thought it was a terrible idea at first – at the time, I didn’t have a very positive opinion about sales. Eventually, after several meetings and being told it could be limited to a 2-year assignment, I agreed to the transfer.

I’m so glad I did. In fact, 2-3 weeks after starting the new role, I was already convinced I wanted to stay beyond the outlined two years. I got to work side-by-side with what became my most inspiring leader and learned so much. First and foremost, I learned I was completely wrong about sales. I never worked harder than I did in my sales role and got insight into other aspects of DENSO – corporate communications, tradeshows, etc. – that I never would have before. And, despite having worked in automotive for more than 15 years, the transfer showed me parts of the industry I had never seen – marketing, product planning, etc.

After some time in the role, I began to feel static and made a move back to engineering, but on the R&D side. Now I get to look at where we are taking DENSO in the future in terms of technology – how do we bring new technologies to automotive, whether it be through innovation, partnering with Silicon Valley companies or start-ups.

I never would have been able to be in this role had I not made that first transfer. In fact, looking back, I feel like my career really didn’t start until I made that move. I wish I had done it sooner. You can only grow so much in a role, then you get comfortable and stop learning.

My Advice to You

If an opportunity presents itself, take it. Even if it seems scary, it will make you grow and become a more well-rounded person. And remember, your human network is the most valuable thing you have, especially in a big company. By making a move, you could double that network.

Search for Open Internal Positions

- Go to densocareers.com

- Click “DENSO Employee”

- Login with your DSC-ID and Oracle Fusion password

- Search for open positions and apply!

The online internal application system only shows non-exempt and exempt office positions at this time. For all other positions, please view local job boards and follow the local application process.

DMAT Celebrates Native American Heritage Month

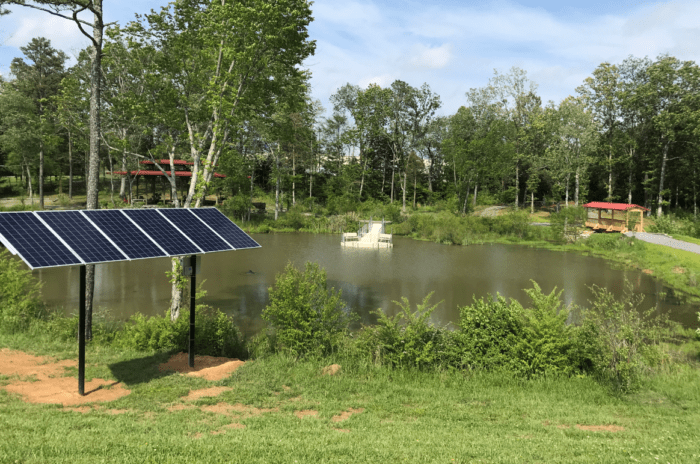

Last month, in celebration of National Native American Heritage Month, the Diversity & Inclusion task force at DENSO Manufacturing Athens Tennessee worked with local authorities to plant a commemorative tree in the DENSO/Athens ECO park to honor the area’s local Cherokee tribe.

History of the Tree

- Scientific name: Aralia Spinosa

- Cherokee name: ultsa gita utana which means “it cuts its top off, large”

- Common name: Devil’s Walking Stick Tree

Cherokee tribe members used the Devil’s Walking Stick in many different ways for medicinal purposes. The crushed roots were used as a salve for healing old sores and a tea, made from the roots and leaves, was used to treat rheumatism. In addition, thorns of the Devil’s Walking Stick Tree were used to scratch the skin when applying medicine, which was believed to give the medicine better penetration into the body. In fact, the wood of the Devil’s Walking Stick Tree would be burned and blown on a scratched area to treat paralysis on half of the body.

What an incredible experience for all to learn more about and celebrate the Native American heritage!

The Devil’s Walking Stick Tree, planted by DMAT associates

Spotlight on Matthew Agius: From Design to Electronics Engineering

Matthew Agius

Electronics Engineer

Transferring from Design to Electronics Engineering

When I was a design engineer in Telematics, I enjoyed my work and team. But the core functionality in a vehicle doesn’t change with each model year, so the system tests and hardware design became repetitive. So, when my manager came across an opportunity and asked if I’d be interested, I said yes. It was time to try something new and I’m comfortable taking risks.

I sat down with my prospective new director who explained the details of the opportunity – the project, structure and team. And while he warned me that it would be something entirely different than what I’ve done before and I wouldn’t know everything at the start, he was very encouraging that I could do it and would get help from others in the department. Knowing all this, especially the fact that he acknowledged I wouldn’t know everything, as well as spending time openly talking to new team members, helped alleviate my fears and concerns.

Admittedly, I felt unprepared. I wasn’t formally trained on the work I’d be doing. But after making the transfer, another recently transferred associate and I were given a project to gauge what we knew. I’m pretty self-motivated so when I come across a task or area I’m not familiar with, I do some research and teach myself. We successfully completed the project, showing the manager and the team our skills and knowledge. It was a great feeling.

My Advice to You:

For those considering a transfer, remember, you’ll never be fully comfortable with a job transition and you won’t master the new job right away – you don’t know everything on day one of any job. Be prepared to fail but know your manager and team members will understand and support you.

I feel like making this change will not only be useful to me personally but for DENSO as I can now bring an expanded skillset to my current and future roles. Plus, I get to work with and learn from DENSO associates across the country.

Search for Open Internal Positions

- Go to densocareers.com

- Click “DENSO Employee”

- Login with your DSC-ID and Oracle Fusion password

- Search for open positions and apply!

The online internal application system only shows non-exempt and exempt office positions at this time. For all other positions, please view local job boards and follow the local application process.

Happy Thanksgiving!

Happy Thanksgiving! We’re so grateful for associates like you, who have been incremental in helping DENSO adapt and thrive in the face of challenging times. THANK YOU for your hard work – it has helped to strengthen our communities, promote safety (on and off the road) and engineer innovation. The holidays may look different this year, but we wish the entire DENSO family a healthy and happy turkey day.

DENSO New Hire Spotlight: Christian Widgren

Welcome to DENSO’s North American team, Christian! Christian relocated from one of DENSO’s European facilities just as countries implemented travel bans to slow the spread of COVID-19.

Originally from Bolivia, Christian was working for DENSO in Germany before he relocated to the U.S. It took him several months to make it over, but Christian’s positive, collaborative attitude throughout the process was immediately noticed by his supervisor. In his new role, Christian is a senior sales planning specialist, focusing on business operations and planning for DENSO in North America.

Despite the uncertainty of COVID-19 restrictions and remote work requirements, Christian says he received plenty of support and patience from his new team as he settled into his new role. Even after he accepted his new position, his management team in Germany worked in collaboration with U.S. management to ensure he had access to the appropriate resources and advice.

While DENSO’s COVID-19 safety precautions mean he hasn’t officially been to his office yet, he still feels as if he knows his team members well.

“I receive constant communications on next steps, including what they’re [DENSO] doing for people who can’t work 100% from home,” said Christian.

Joining DENSO’s North American team felt like a step-up in Christian’s career. Not only does he have access to top-of-the-line tools and support, his role and the professional development available to him align well with his interests and career goals.

“The automotive industry is already seeing a big shift, and being a part of this from a supplier point of view is interesting,” explained Christian. “It will be really exciting to see how we support a new era of autonomous and electric vehicles, and become more of a software industry supporter as well.”

If you’re interested in growing your career and shaping the future of mobility, check out our open positions here: https://densocareers.com/

Congratulations 2020 TPD Contest Winners & Participants!

The DIAM Technical Presentation Development (TPD) Contest is an opportunity for engineers to showcase their projects, while competing in front of a panel of judges for best overall presentation and insight into problem-solving, innovation, efficiency or other aspects of the project and process.

This year’s contest, held Nov. 19, was the first time the event was in a virtual format, adding a new level of challenge for participants. Please join us in giving a round of applause to all our participants for their hard work, preparation, and flexibility.

Congratulations to our winners!

First Place

Peter Atencio, PG3

Topic: Laser Welding – Optimization for your Application

Second Place

William Bickel, PG2

Topic: RU COM Development & Validation

Third Place

Eric Armbruster, PG3

Topic: Trailer Detection and Size Estimation Using Rear Corner Radar

Great job participants!

| Participant | Group | Topic |

| Dan McGrail | PG2 | Novel Design of a High Force Density Solenoid |

| Eric Armbruster | PG3 | Trailer Detection and Size Estimation Using Rear Corner Radar |

| Vincent Lee | PG2 | D2UC wipe quality issue |

| Christian Munte | PG3 | Mobility Platform Over the Air Update (OTA) |

| Matt Johnson | NAREC | Park Place: A new mobility opportunity takes a back seat to save $50M |

| Peter Atencio | PG3 | Laser Welding: Design Optimization For Your Application |

| William Bickel | PG2 | Alternator Design & Development for GMET6 Engine |

| Mike Pinger | PG1 | HVAC Heat Pickup |

| George Hadley | PG3 | RCCM Calibration Automation Development |

Legacy Associate Spotlight: Dwayne Taylor

We are so grateful for the people who make careers for themselves at DENSO. These individuals repeatedly show the values key to DENSO Spirit — foresight, credibility and collaboration — and continually strive to make DENSO a great place to work, all while delivering exemplary service to our customers and communities.

Over the next few weeks, we’ll introduce you to some of DENSO’s longest-serving associates. They’ll share what drew them to DENSO and more importantly, why they’ve stayed.

Meet Dwayne Taylor. Dwayne first joined DENSO’s Southfield, Mich. location back in 1986!

Dwayne says he was initially attracted to DENSO because the products we were creating looked advanced and interesting. When he first started, we were sharing office space with a drive-thru bank! That’s hard to believe when you think about the size of our campus now. Our Technical Center building in Southfield was completed a few months after Dwayne joined and we moved operations there.

Dwayne also says that DENSO’s commitment to quality, advanced technology, and its associates are what’s made him stay all these years. He says over the years while the methods have changed, the company has grown both locally and globally, and the industry has adapted to the changing market, DENSO’s commitment to these areas has remained strong.

One of Dwayne’s favorite memories from his time at DENSO was the opportunity to work as an expat in Japan. Living and working in Japan gave him and his family a whole new appreciation for what life is like in and outside of Japan and it’s an experience they really enjoyed and will never forget.

For prospective DENSO associates, Dwayne advises to always put forth your best effort, take advantage of opportunities to learn, and recognize that DENSO strives to offer the best in every sense of the word. He also notes that DENSO is a strong and stable global company and opportunities exist to gain experience abroad – plus it’s a great team to be a part of!

If you’re interested in a lifelong career shaping the future of mobility, check out our open positions here: https://densocareers.com/

Veteran Testimonials: Mark Lewis, Section Leader EDGE Project Team

This month, we’re spotlighting military veterans to thank them for their hard work and DENSO Spirit. Mark Lewis, Section Leader of the EDGE Project Team at DENSO’s Battle Creek facility had this to say about his military service and subsequent time at DENSO:

“The military helped me to be disciplined in my approach to things. It also taught me to trust my team.

When I started at DENSO, they embraced the team culture and were very organized, regimented similarly to the military. I felt very comfortable in this environment and throughout my career it has helped me to develop into the leader (and person) I am today.

DENSO also supported me financially and emotionally during my first year of employment. I was called to Active Duty by the Michigan National Guard to go to Desert Shield/Storm from 1990-91. Even though I spent more than six months on deployment overseas, they would check in on my family and kept my pay at a normal level!”

Please join us in thanking Mark for his service! And, if you know a veteran we should spotlight, tag us on social media or email densospirit@outlook.com.

Manufacturing Month: Back to Manufacturing

As part of our continued celebration of Manufacturing Month, we hosted a panel discussion last week that focused on two associates who left not only DENSO but the manufacturing industry altogether for other job opportunities – only to come back!

Ed Fellows and Rich Stanley – both in Battle Creek, Mich., shared their stories about how they got started at DENSO – Rich on the assembly line and Ed as an engineer – how they advanced, why they left and, more importantly, why they came back.

We also took a few minutes to bust some serious myths about manufacturing. Make sure everyone knows our is exciting, clean and full of advancement opportunities for creative and critical thinkers alike! You can watch the full discussion here: https://www.youtube.com/watch?v=nPaUh2PPyhY&feature=youtu.be

Spotlight on Eric Stevens: My Journey to Sales

Eric Stevens

Account Manager, General Motors

Transferred from Talent Acquisition to Resident Engineer in Electronics to Sales in Thermal Engineering

Like many people, there have been several stepping stones in the path my career took to get me where I am today. I joined the talent acquisition team at DENSO nine years ago with a goal to someday land in a sales position. During that time, I recruited for the resident engineer position within the electronic components team a handful of times. Then one day when there was another opening, I was asked if I’d be interested in the opportunity. Though I had zero engineering experience, I knew this would be an incredible opportunity as I worked my way toward a sales position.

But this was a BIG change, so I had a lot of conversations with my current manager and mentor as well as external contacts I respected. In the end, I realized that not many people get HR and engineering experience on their way to sales, so I worked with my current and future managers to develop a transitional plan. I believe having that plan, one that everyone assisted in developing and thought was fair, was a key to my success. Another success factor was communication – I can’t stress how much ongoing communication, maybe even overcommunicating, helped ease my stress and anxiety.

Then, after three years as a resident engineer on the GM account, one of my directors asked what my next step was because he knew of a sales opportunity. I liked my job, but being in sales was my goal, and I don’t have an engineering degree, so there were limitations on how far I could go in that area. However, while the sales position was with my current customer, GM, it was in Thermal Engineering, a new product area for me. So once again, I was faced with a challenging decision. I had a lot of conversations with people to know exactly what I had to do to leave one position and start another. Being the competitive person I am, I saw the opportunity as a positive challenge, something that would show I could improvise and overcome obstacles that may seem like a roadblock or boulder in my career path.

During both transitions, I not only received support from managers, but the folks in HR training did a great job in ensuring I got the necessary training needed for each new job. I went through a lot of training.

I’m not sure I’d be in my current position if I didn’t take those big steps. So, my advice to anyone who’s had even just one thought about pursuing an internal transfer, is to look into it. Yes, it can and probably will be scary or challenging at times, but at the end of the day, it could be incredibly beneficial to you and the company. I know the experience I gained through my transfers is unique and will continue to help me flourish throughout my career.

Search for Open Internal Positions

- Go to densocareers.com

- Click “DENSO Employee”

- Login with your DSC-ID and Oracle Fusion password

- Search for open positions and apply!

The online internal application system only shows non-exempt and exempt office positions at this time. For all other positions, please view local job boards and follow the local application process.

Spotlight: Krazy for the Kazoo

Earlier this month, DENSO employees/associates from our thermal manufacturing facility in Battle Creek, Michigan, participated in the Krazy for the Kazoo Day, a community event aimed at beautifying the city. The group, along with others in the community, picked up a combined total of 72 bags worth of trash, cut down enough brush to fill over two semi-trailers (estimated to be 6,240 cubic feet of brush!), and planted 30 native plants.

Not only was this event great for the community, DENSO Spirit shined bright through the collaboration, teamwork, and Kaizen demonstrated by the associates/employees who participated.

We chatted with Jody Smith, an engineer in Battle Creek, who spearheaded the activity, to learn more about how DENSO got involved. Here’s what she had to say:

What is Krazy for Kazoo?